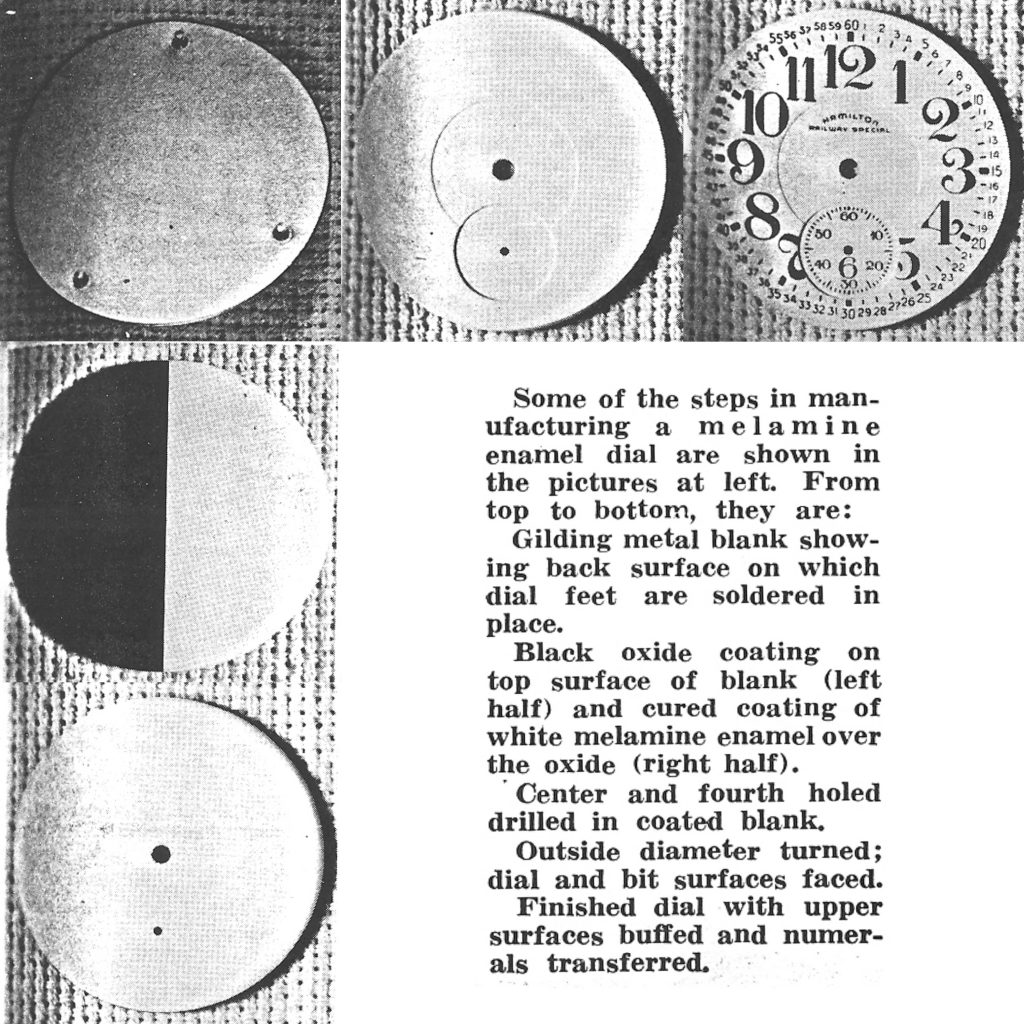

The Hamilton Watch Company Melamine Dial: Hamilton Research and Adoption Timeline: Part 1

Following extensive experimentation with nearly forty materials to find a suitable replacement for vitreous enamel, the Hamilton Watch Company began the finalization process for the new material in 1946.

According to company memos, a report was presented on June 20, 1946, detailing the progress of the melamine dial project:

“Mr. Vermont commented favorably upon the appearance of 16 size Melamine enamel dials he had seen. Mr. Shubrooks stated that development work on the Melamine enamel dial project was still underway and that consequently present production costs were still higher than they would eventually be. Mr. Shubrooks indicated that a progress report on recent activities in the Melamine dial project would be available soon in the Library.”

On August 22, 1946, an updated report was provided detailing recent progress after the initial operations of an experimental lot of 300 melamine dials was finished:

“Mr. Shubrooks reviewed recent and promising progress in the project of developing melamine enamel dials. An experimental lot of 300 16 size, double sunk, melamine dials, part #6536, was closely followed through processing on Shop Order #70070. Of 300 dials started, 219 were finished up to transferring and were submitted for inspection. A total of 64.42 hours were required for machining and polishing. At 75 cents per hour for labor the total cost of each dial for machining and polishing operations was 83 cents. At 80 cents per hour for labor the total cost of each dial for machining and polishing operations was 87 cents. These cost figures include overhead and may be compared to a standard cost of $1.75 each for vitreous enamel dials. Comparative cost figures include transfer costs although the transfer work must yet be done on the melamine dials.

It was emphasized that after transferring the dials must yet be subjected to final inspection. It was believed possible that melamine dial costs might be still further reduced as the process becomes established.”

On October 3, 1946, a new reports that the experimental batch of melamine dials had been completed:

“In a memorandum, dated October 3, 1946, Mr. Morgan informed Mr. Manby that transfer work was completed on the 16 size dials, part #6536, produced under S.O. #70070. They were given a finish inspection, a transfer inspection, and a final inspection. A third progress report on Project #5002, “The Development of Melamine Dials,” was prepared by Mr. Earl Walters, the project engineer. This report brings the project up to date including final approval of the above mentioned finished dials. Included is a chart which records the time, spoilage and possible reason and recommended procedure for correction of each operation. The approximate cost, based upon these figures is also included.

Mr. Morgan suggested that the next logical step would be to have authoritative decision on the “when and how of production.” It was recommended that a conference of the proper authorities and interested parties be called for a decision on this matter sometime in the near future.”

The following week, a joint conference was organized to discuss scaling the production of the new melamine dial. [Continued in Tomorrow’s Post]

Love to read your articles. Great research!