The Hamilton Watch Company Melamine Dial: Hamilton Research and Adoption Timeline: Part 3

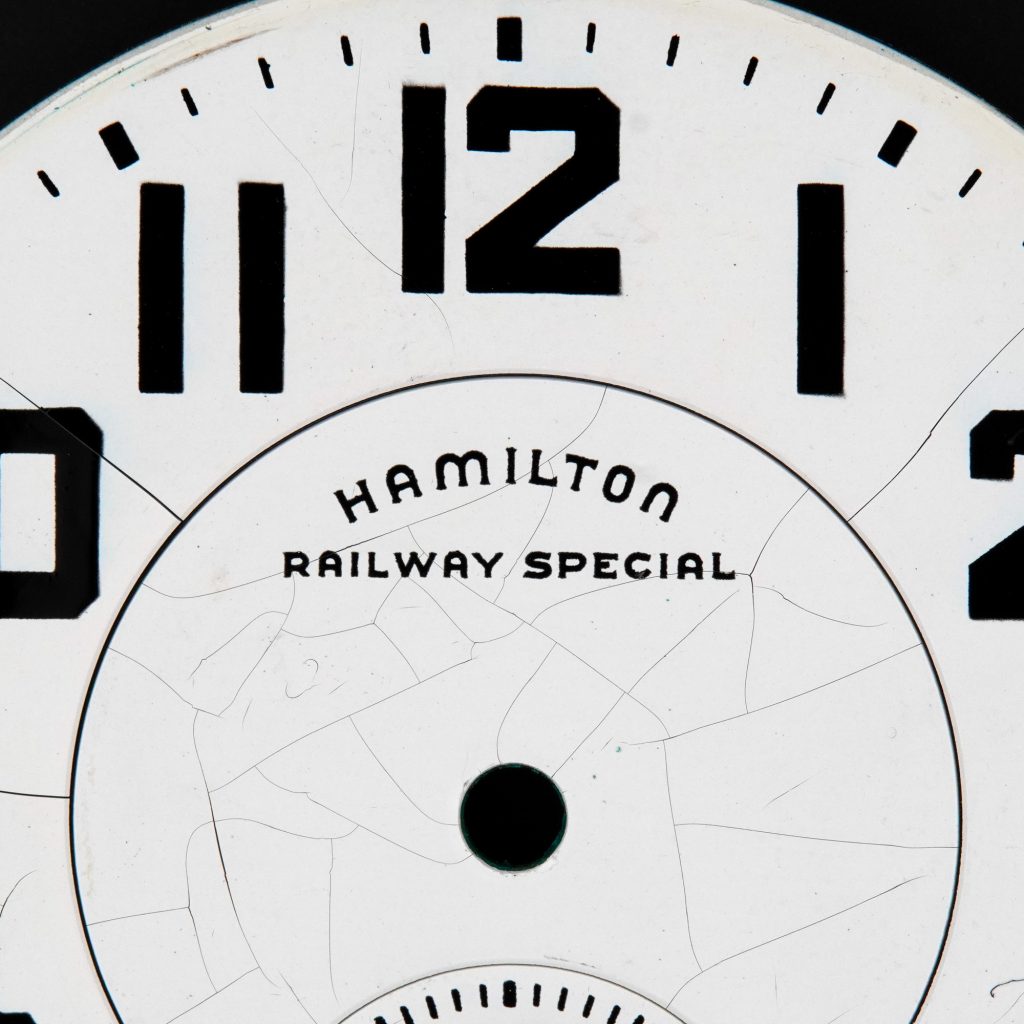

The meeting organized at the Hamilton Watch Company on October 10, 1949 set forth the scaled production of new melamine dials with the objective to provide an alternative to the vitreous enamel on the company’s 16-Size railroad dials.

Company memos detail the conversation, including a concern about discoloration and deterioration of the new material:

“It was stated that there would be an order placed from the Sales Dept. calling for 2000 dials to be made according to the new drawing #50-121, There was some discussion on the use of automatic machines and it was then ordered that while this lot was being produced, Mr. Connor should obtain estimates on the equipment required for processing all the railroad watch dials in melamine. Mr. Schwalm stated that a production of approximately 4000 per month would be required.

Mr. R.B. Hershey raised a question regarding discoloration and deterioration of the enamel. It was explained that while the material was comparatively new (1939) it had served well in other applications. The results of laboratory tests for color fastness and deterioration were briefly sketched in answer to this question.

The main reasons for spoilage in processing were brought up by the writer. These reasons were the machine chatter marks, the closing of the center and fourth holes with enamel, and out-of-level trays. Recommendations were made to correct these difficulties and reduce the subsequent spoilage. Mr. B.E. Wolfe stated it would be possible to turn up a burr on the edge of the dial which would eliminate some of the enamel application difficulty.

Mr. Hershey was instructed to order sufficient brass stock for 4000 dials. It was stated that the brass ordered last year for this purpose had been received [?]. Some difficulty was expected in obtaining brass on future orders. However, it was believed that the stock on hand might be sufficient for the present order.

Mr. Frey then brought up the matter of an insoluble red transfer paint. It was explained that some of the dials required certain figures to be transferred in red and the laboratory was instructed to work on this problem.

Mr. S. Griffiths of Watch Design stated that the new drawing, #50-121, for the melamine dial would be completed by next Tuesday.

The meeting adjourned at 2:20 P.M.”

These articles about the adoption of melamine dials are very interesting. I have a watch with such a dial and the melamine does not have cracks! While I routinely carry watches in my collection, I’m reluctant to carry this watch and end up with cracks on the dial. I’ve decided to keep the watch in storage and hopefully preserve its condition.

I have been an avid Hamilton collector for over 46 years! The worst part that Hamilton put out, was the Melamine dial!!