Rockford Watch Company Grade 545 Railroad Grade Movement Rating Certificate

Around 1906, the Rockford Watch Company attempted to gain more market share by leveraging stricter specifications required for railroad service watches. To further reinforce the precision and reliability of these watches, the company also offered a certificate of rating upon request.

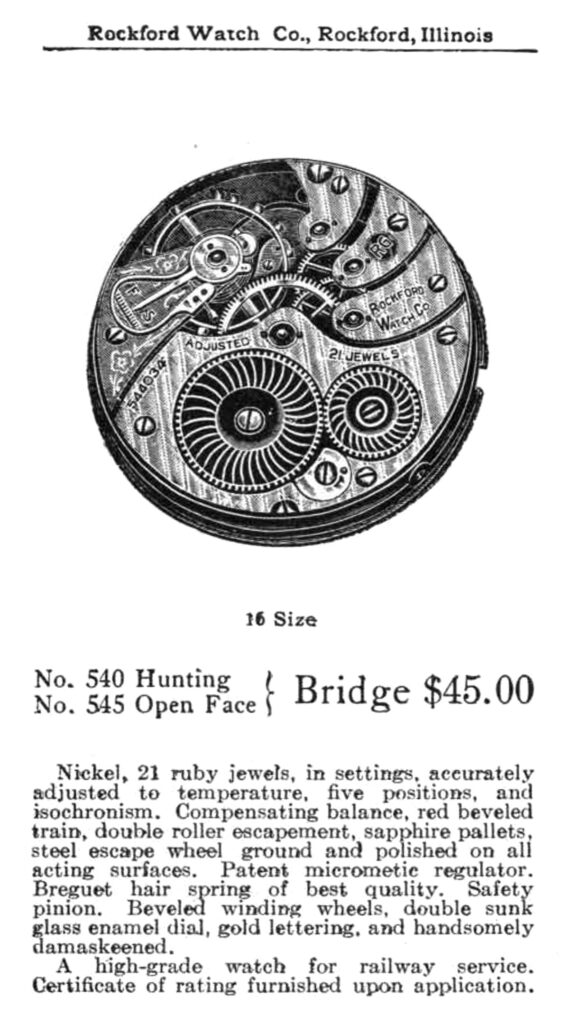

Rockford’s railroad grade movements were frequently advertised in catalogs as: “A high-grade watch for railway service. Certificate of rating furnished upon application.”

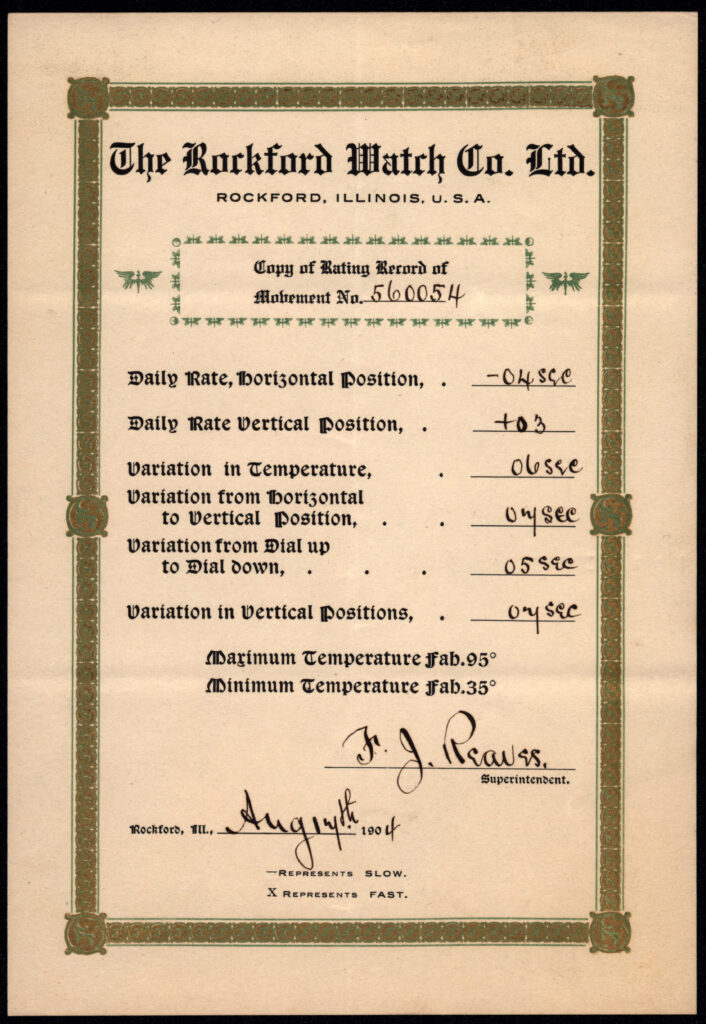

The rating certificate detailed the timing deviations of the movement in positions and temperature – crucial measurements for a watch designed to be used by railroad workers. These serialized certificates also featured the signature of the factory superintendent to ensure authenticity and authority.

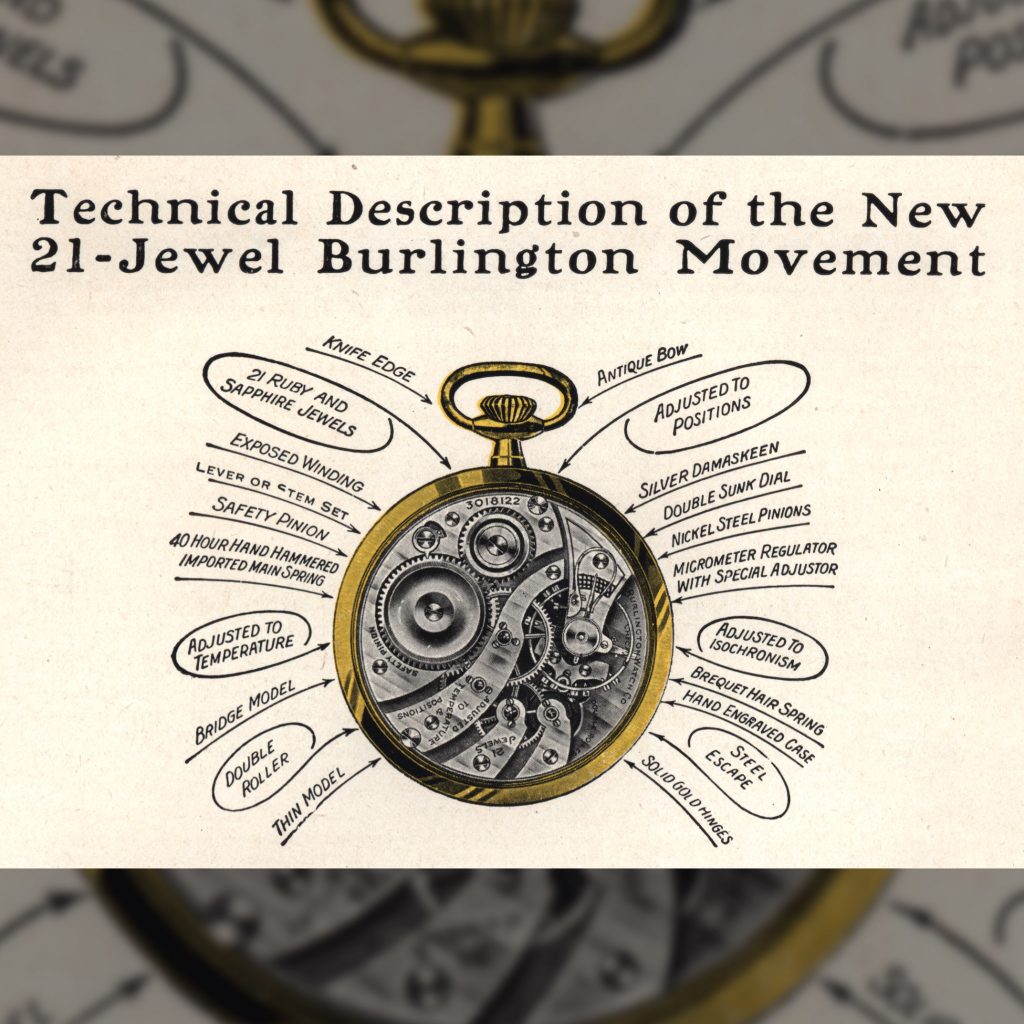

The certificate accompanying this article was issued for Rockford movement #560054, classified in factory serial lists as Grade 545 (16-Size, Model 5, Open-Face, 21-Jewels). The c.1907 Rockford Catalog described the No. 540/545 as “accurately adjusted to temperate, five positions, and isochronism.” The availability of an official rating certificate is also noted at the bottom of the catalog page.

By analyzing the rating certificate with the grade description, we gain insight into some of the adjustment practices at the Rockford factory during this era.

For example, the maximum temperature is defined as 95 degrees Fahrenheit, and the minimum temperature is shown to be 35 degrees Fahrenheit. With this information, we learn that the temperature extremes used at the factory for adjustment were 35 degrees for cold and 95 degrees for heat. Skilled adjusters at the factory would meticulously time the movements in temperature-controlled boxes and then modify the locations of the balance screws until the temperature compensation became balanced between the heat and cold environments.

We also have insight into how the positional adjustments were measured.

The first measurements recorded are the “daily rates” for the horizontal and vertical positions. These figures represent how many seconds the movement gained or lost in those positions during a period of 24 hours. The “vertical position” is synonymous with the standard “pendant-up” position. However, it is unclear in the “horizontal position” represents the standard pendant-left or pendant-right position – or an average of the two.

The “variation” measurements reflect the difference between the ratings in opposing scenarios. For example, the variance in temperature – compared between 35 degrees and 95 degrees – was recorded for movement #560054 as 7 seconds. Since the absolute measurements were not included, it is difficult to determine if the rating measurements were slower, such as -21 and -14, or faster, such as 7 and 14. Each factory maintained detailed tolerance specifications related to each grade or class of movements. For a high-grade movement like the Grade 545, the ratings in the two temperature extremes likely average close to zero.

Next, the variation in the horizontal and vertical positions was logged, consistent with the rating measurements included near the top of the certificate (absolute difference between -4 seconds and 3 seconds = 7 seconds).

For this movement, the dial-up and dial-down variance measurement was specified as 5 seconds. Again, without the exact rating measurements, it is unclear if this represents fast or slow, but the difference between the dial-up and dial-down positions was 5 seconds. It should be noted that when watches were adjusted at the factory, it was more important to achieve a balance between the extremes rather than to expect the elimination of rate error in all positions and temperatures.

Lastly, the variation in vertical positions was logged as 7 seconds. This is likely the variance between the pendant-up and pendant-down positional rates.

With this information, we can conclude that the factory timed movements in the following positions: pendant-up, pendant-down, horizontal (pendant-left, pendant-right, or an average), dial-up, and dial-down.

When movements were adjusted at the factory, ratings would be logged on cards for reference. Adjustors would adapt the watch according to the results and time the watch again. This process would be repeated until the movement achieved precision within the specified tolerances.