Private Label Trade Names on American Pocket Watches: The Non-Magnetic Watch Company: Part 31: The Giles and Gribi Debate: Anti-Magnetic Shield versus Non-Magnetic Alloys

As non-magnetic watches and anti-magnetic shields gained popularity with a growing concern over electromagnetism, each became subject to attacks from interests supporting the alternative solution.

This battle played out most fervently in a series of demonstrations, papers, and letters between Charles K. Giles and Theo Gribi in 1887 and 1888.

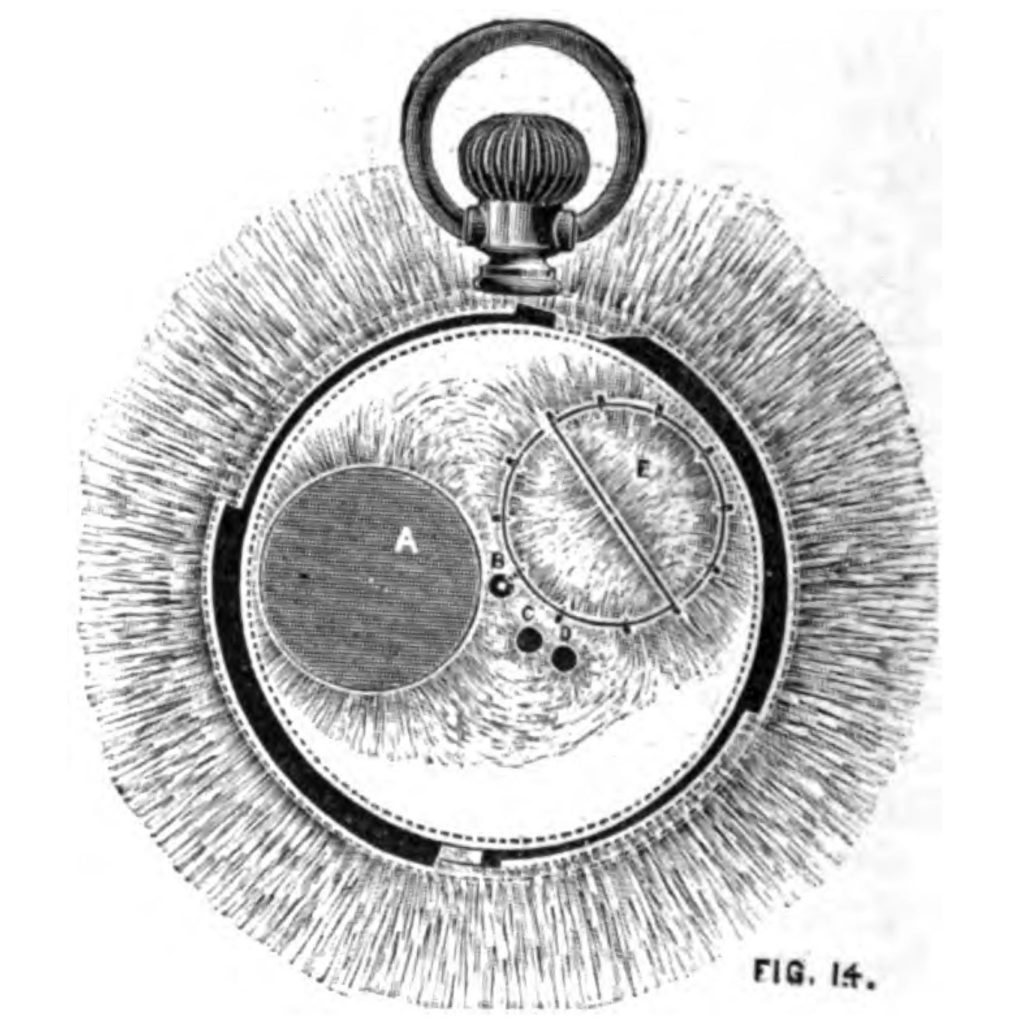

On December 5, 1887, Charles K. Giles, inventor and promoter of the Giles anti-magnetic shield, presented a paper before the Chicago Electric Club explaining how the shield effectively protected against electromagnetic fields. The paper was subsequently published in the December 10, 1887 issue of the Western Electrician.

Mr. Theo Gribi wrote a detailed response to the paper criticizing the faults of Giles’ demonstrations and, instead, praised the effectiveness of non-magnetic alloys used by the Non-Magnetic Watch Company. Gribi claimed that the anti-magnetic shield simply degraded the magnetic field but that the rate of the watch was still influenced by magnetism.

This set off a series of exchanges between the two men debating the effectiveness of non-magnetic alloys and the validity of the shielding theory.

In the June 30, 1888 issue of the Western Electrician, Giles published a response directly addressing the advantages of steel over non-magnetic alloys in watchmaking:

“In these non-magnetic metals, the necessary compactness for elasticity must be obtained by physical force, compression, rolling, or by hammering; in actual use, this same force is operating to undo the work it has done before and it will accomplish sooner or later. On the other hand, steel is the only metal which can be fire-tempered, or reduced to a condition of extreme compactness and elasticity, without the aide of physical force; it has the property of elasticity to a greater extent than any other known metal – its molecules seem to have the power of sliding one by the other, and returning to, or retaining, their original position – a sort of inter-crystalline elasticity, not possessed by any of the non-magnetic metals – a sort of “magnetic life.” as it were; its magnetic and elastic capabilities seem to go together; if you reduced this steel to such a state of softness as to destroy its elasticity, it would correspondingly reduce its magnetic power; steel is, pre-eminently, a metal possessing “magnetic life.””Charles K. Giles, “Magnetism in Watches,” The Western Electrician, June 30, 1888

Giles then referred to recent reports that non-magnetic alloys initially respond well in tests but eventually lose elasticity:

“Numerous experiments with alloys of platina have developed the fact, that while balances made from platina alloys are sometimes very promising during the first few months of performance, they invariably undergo a change after being some time in use, which destroys the accurate compensating qualities of the balance.”Charles K. Giles [Quoting a Third Party], “Magnetism in Watches,” The Western Electrician, June 30, 1888

Despite Giles’ claims that non-magnetic alloys lose effectiveness over time, plenty of surviving examples fitted with Paillard’s non-magnetic alloys still operate with impressive precision to this day.

1 Comments