Private Label Trade Names on American Pocket Watches: “Burlington Watch Co.” Part 14: Adjusted to Positions

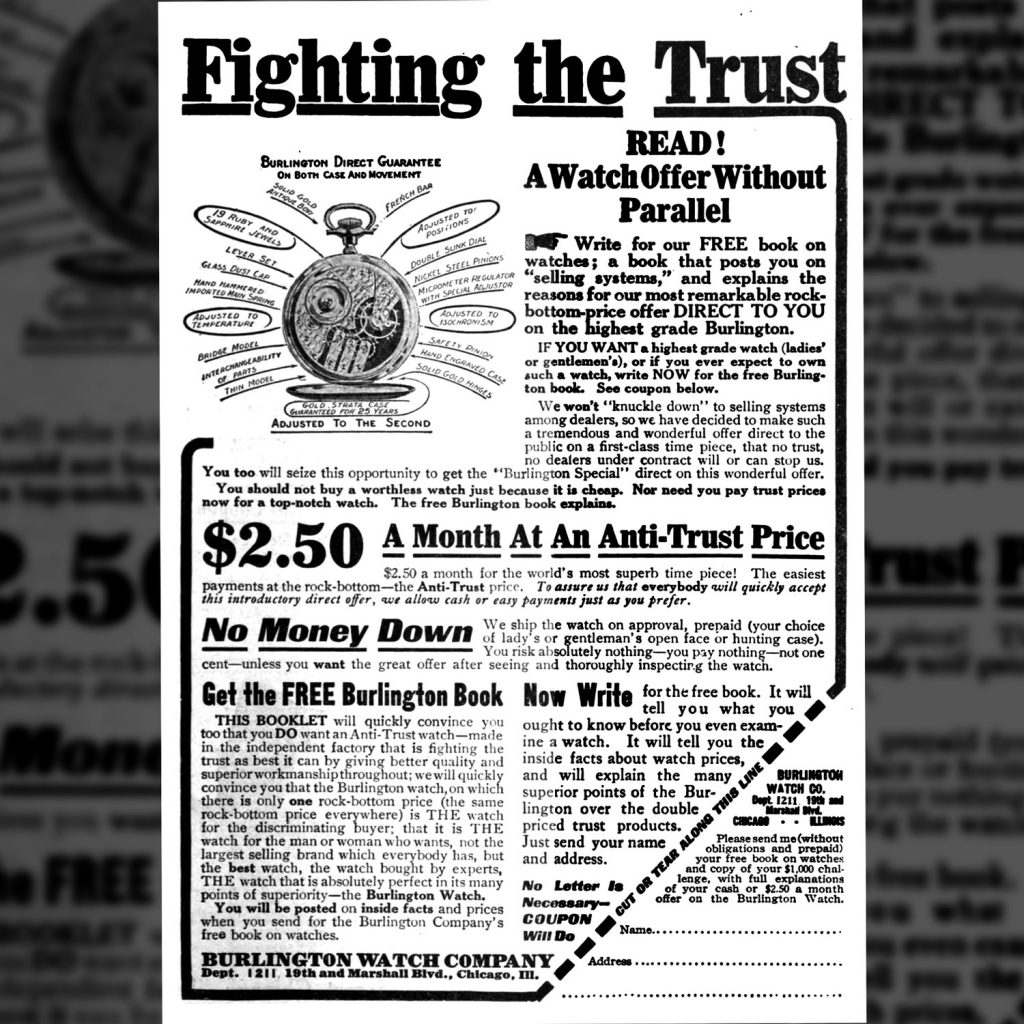

The second-generation 16-Size “Burlington Special” (Grade 185) was described in catalogs and advertisements as “Adjusted to Positions.” From the summary presented in the c.1911 Burlington Watch Company catalog, we can infer that the Grade 185 “Burlington Special” was adjusted to three positions, consistent with the standard Grade 185 produced at the Illinois Watch Company factory.

“Adjusted to Positions. This adjustment cannot be made until after every other adjustment has been made. The other adjustments to temperature and isochronism are made with the watch in an upright position, that is, the stem pointing up. Adjusting a watch to positions is adjusting it so it runs the same in all positions. For instance, if the watch is face down all the bearings are resting on an end. If the watch is face up, they are resting on the other end, and if the watch is stem up the bearings are not resting on either end but on the side. You can easily see that if a watch is to run absolutely accurate the friction of the bearings must be exactly the same for all these positions. As the Burlington Special is adjusted to positions (not to position, but to positions) you can readily see friction will always be the same and your watch will run accurate no matter in what position you may carry your watch in your pocket. This adjustment to positions is never attempted on more than a very, very minute percentage of all watches made in the United States. Remember every Burlington Special is adjusted to temperature, adjusted to Isochronism and adjusted to positions. Every Burlington Special is a masterpiece.

Ordinary watches are often “adjusted to the person” in a sort of a way by the local jeweler. This helps of course toward making a watch nearly right, but the Burlington Special, all adjusted at the factory, and accurately adjusted and made right, of course requires no such “personal adjustment.”c.1911 Burlington Watch Company Catalog

Interestingly, the description conveys that the positional adjustments are conducted to correct differences in friction when the pivots are resting in certain positions. While friction certainly plays a role in determining the accuracy of a watch, gravitational forces have a more significant influence on positional rates. When the watch movement is adjusted to positions at the factory, the balance is properly poised to equalize the weight. This adjustment process reduces poise errors, resulting in a watch that maintains the same average rate in different positions within a defined tolerance.