Elgin Going Barrel vs. Patent Safety Barrel

Starting in 1898, new models introduced by the Elgin National Watch Company began featuring George Hunter’s patented safety barrel design, removing the necessity of a safety pinion on the center wheel and providing a more robust winding system.

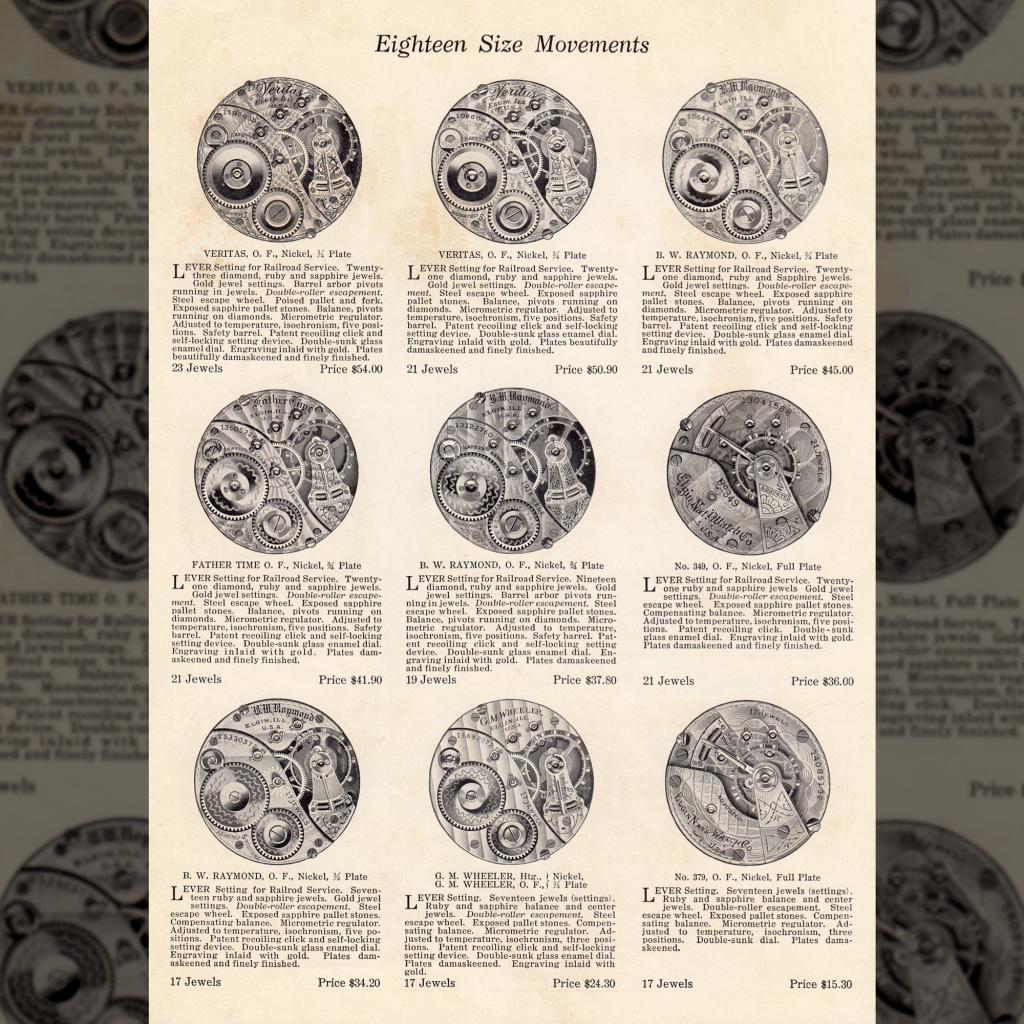

In the accompanying image, the traditional going barrel is compared to the patented safety barrel fitted in Elgin’s new movements, including the prestigious “Veritas Model.”

The safety barrel design is characterized by the mainspring being coiled within a separate steel barrel, providing the ability to absorb the force when the mainspring breaks without expelling damaging shock to the train. When distinguishing the different barrel classifications, it is easier to consider the separate barrel containing the mainspring as the “safety barrel.” Movements that feature this separate spring barrel are fitted with “safety barrels” while others are not.

Without the mainspring being attached to the toothed wheel, as it is in the going barrel, the driving force must originate from the barrel arbor instead. For this reason, the effective design requires the spring barrel to rotate while the watch is wound and the arbor wheel rotates while the watch is running, rotating the toothed wheel and providing energy to the train.

This operation has an opposite arrangement in the going barrel. When the watch is wound, the barrel arbor is rotated, coiling the mainspring within the toothed barrel. When the watch is running, the entire barrel rotates to provide energy to the train.

It is important to note that these two designs are also distinctly different from the motor barrel design, though they are often conflated.

1 Comments