What is a Motor Barrel?

Following yesterday’s post comparing Elgin’s going barrel to the patent safety barrel, there were questions regarding the distinction between these designs and the motor barrel. Today, I will provide a brief synopsis and save a more detailed comparison for a future post.

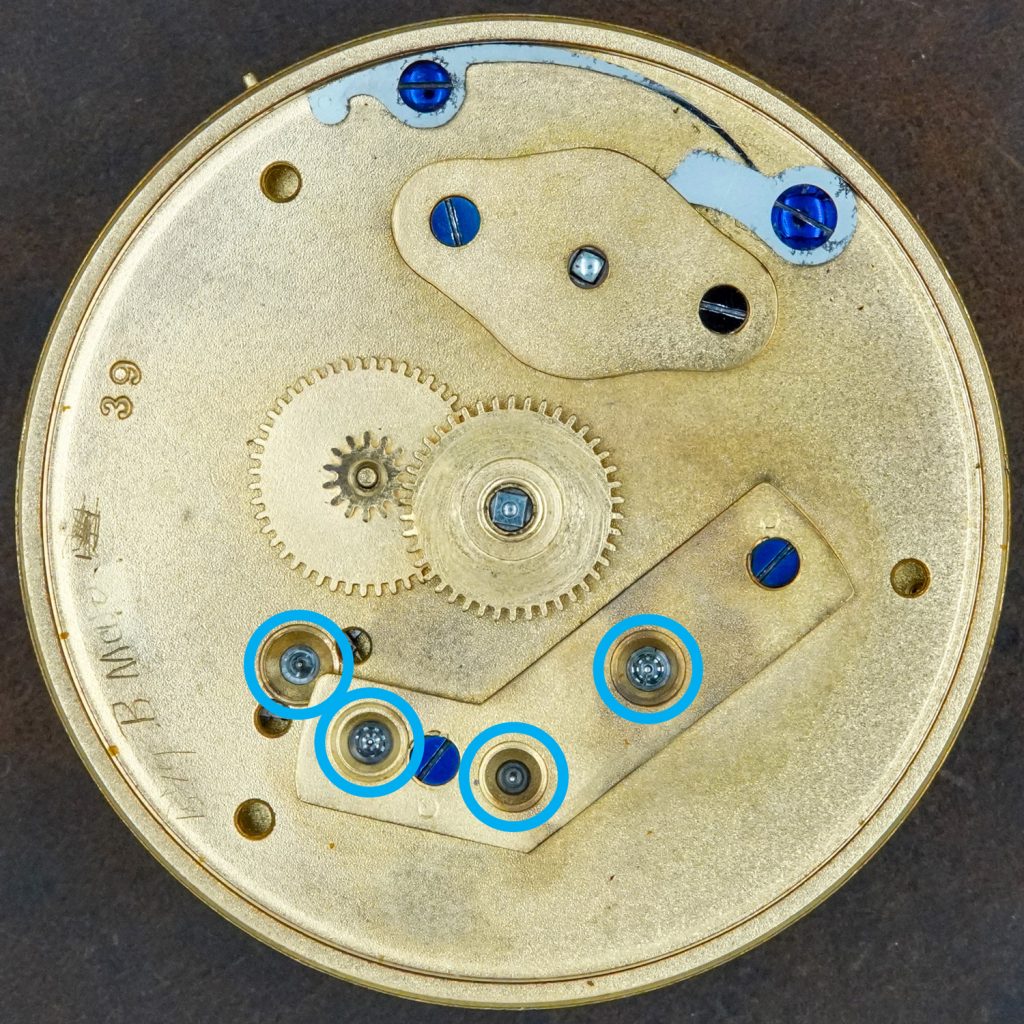

Many movements equipped with a safety barrel feature a hub on the ratchet wheel with three screws. Because of the identical outward appearance found on motor barrel designs, the safety barrel is frequently conflated with the motor barrel. However, these barrel systems are distinct and the terms should not be used interchangeably. The confusion becomes even more problematic due to curriculum from watchmaking schools that fail to draw this distinction.

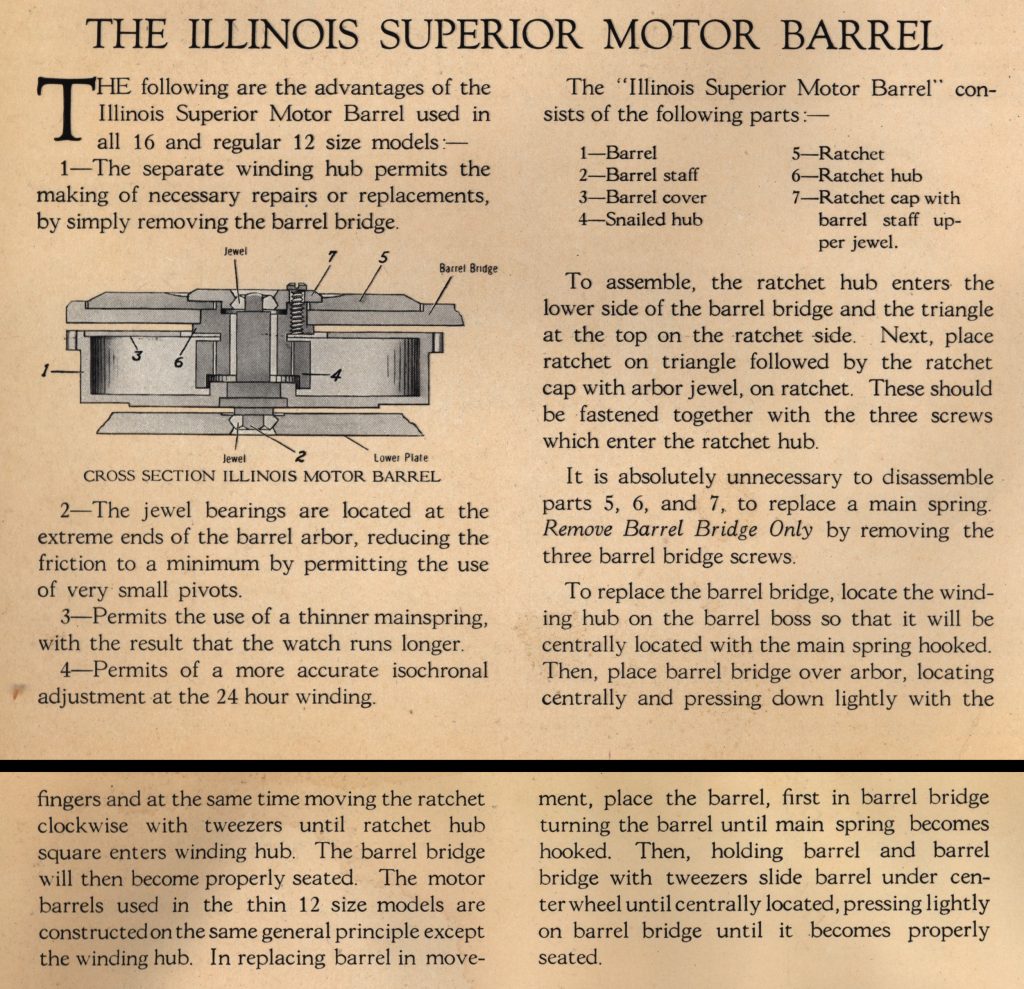

The motor barrel is similar to the going barrel except the barrel jewels can be beneficial while the watch is running. This is accomplished by a staff rigidly attached to the barrel that projects through the hollow mainspring hub and acts as an axle. The mainspring hub is journaled to the ratchet wheel so that while the watch is wound, the arbor is rotated to coil the mainspring, similar to a going barrel. While the watch is running, the barrel rotates via the “axle” inside the hollowed snailed hub. This allows the system to be functionally jeweled on the upper and lower pivots, in a similar fashion as the safety barrel design. In essence, the motor barrel operates like a going barrel with the benefit of being functionally jeweled like a safety barrel.

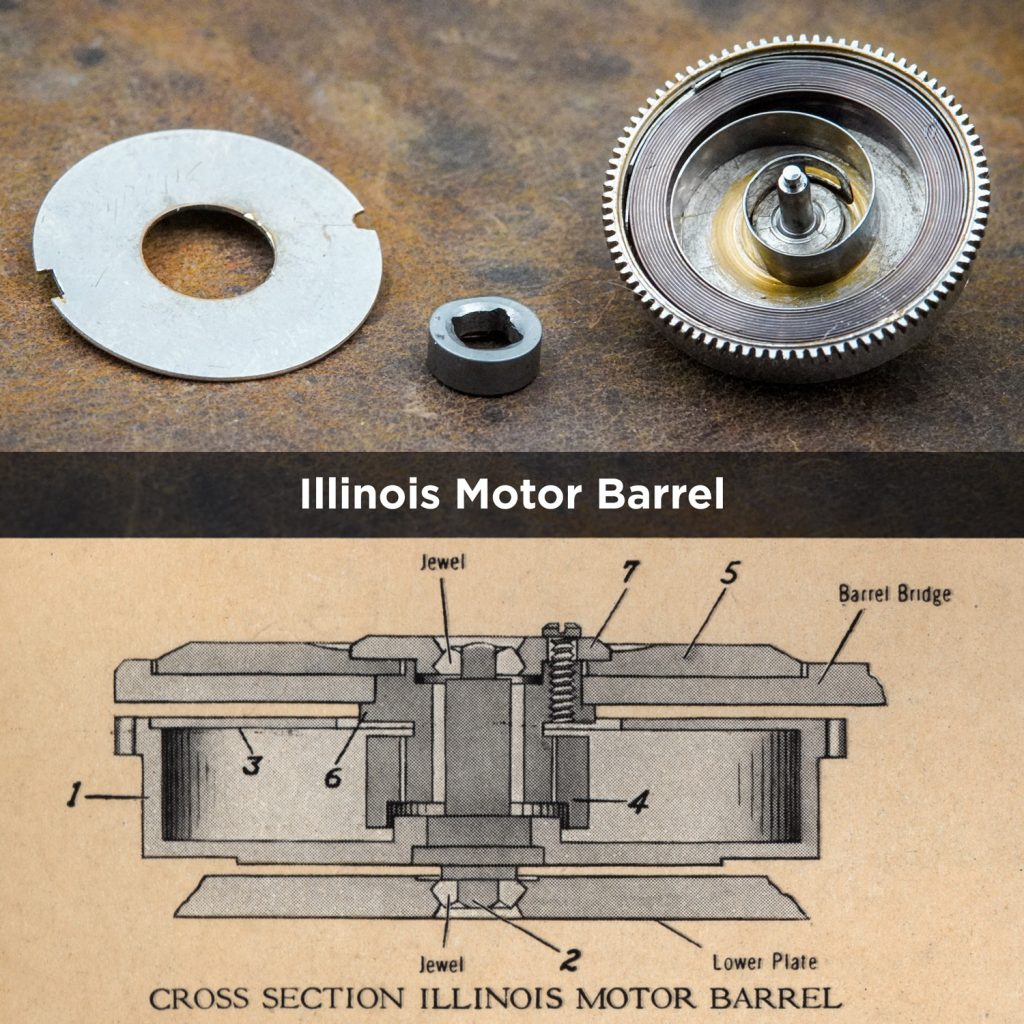

The accompanying image shows the motor barrel from an Illinois Bunn Special exhibiting the center barrel staff with the diagram of the Illinois “Superior Motor Barrel.” Similar designs were used by Hamilton, and Elgin even created two premium 16-Size grades in the 1930s that featured the motor barrel: Grade 494 and Grade 540.