The Hamilton Watch Company Melamine Dial: Hamilton Research and Adoption Timeline: Part 2

After the experimental batches of the new melamine dials proved to be a success, the Hamilton Watch Company met to finalize the production plans for the new dial.

On October 10, 1946, the success and possible issues with the dial were discussed during a joint conference, detailed in company memos:

“A meeting of the regular members of the Materials Committee was assembled jointly with invited authorities from various departments to discuss ways and means of expediting the adoption of 16/S melamine enamel dials. The following were present in Mr. F. Hauer’s office at 1:30 P.M., October 10, 1946, at which time the meeting was called: Miss E. Schultz, Messrs. M.F. Manby, G.E. Shubrooks, D.C. Connor, T.R. Schwalm, H.L. Hovis, M.L. Erb, F.A. Hauer, R.B. Mentzer, P. Frey, A. Marked, R.B. Hershey, B.E. Wolfe, H.C. Dobbs, S.R. Griffiths, H.S. Morgan.

The chairman, Mr. Manby, opened the meeting by briefly describing the project and the reported results of the first experimental lot of melamine dials produced in the Dial Department. The recent approval and endorsement by the Sales and Styling Divisions on the use of this melamine dial on railroad watches was mentioned. Mr. Manby then accepted the questions and subsequent discussion into the channels concerned with the future production processing of these dials.

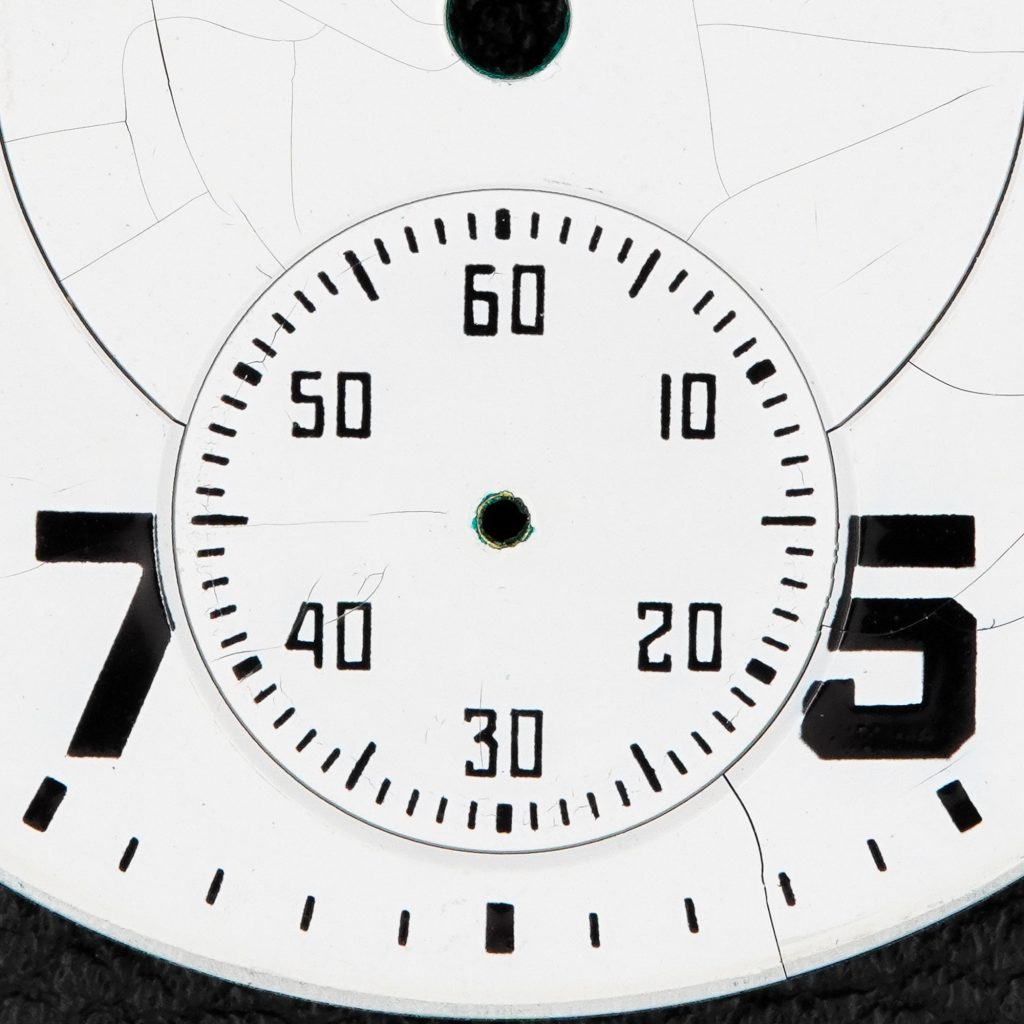

Mr. P. Frey of the Styling Division stated that he had selected 12 dials for standards and that these were properly distributed. He also stated that a new transfer plate will be needed because of the objectionable transfer of the figures 5 and 7 which, on the present plate, extended into the sides of the bit. Miss E. Schultz explained that there were about ten different styles of 16/S dials and that new plates would be required for each of these.

The use and demand for the single and double sunk dials was then discussed. It was pointed out by Mr. Manby that the double sunk dials were definitely preferred but that in the past the single sunk dials were acceptable to the trade mostly on the basis of scarcity of double sunk dials. Instructions were issued not to place any future orders in the Dial Dept. for single sunk 16/S dials.

Mr. T.R. Schwalm was questioned about going into full production on this type of dials. Mr. Schwalm explained that this was impossible with present equipment, and that he would require at least 3 additional lathes to produce all the dials in melamine. He also explained that the personnel problem in connection with 16/S dial may delay the progress somewhat. However, Mr. Schwalm stated that he believed these problems could eventually be overcome and that the total cost of the melamine dials would be considerably less than the present vitreous dials. Mr. D.C. Connor then submitted a rough estimate on the possible savings which was approximately $1.16 per dial.”

![New York Standard, Grade 41, c.1895 [Movement Image] img](https://blog.pocketwatchdatabase.com/wp-content/uploads/2022/01/129790290_178097760636911_5132318547637788034_n-1024x1024.jpg)