The Original Quartz Watches: Enamel Recipe for White Watch Dials

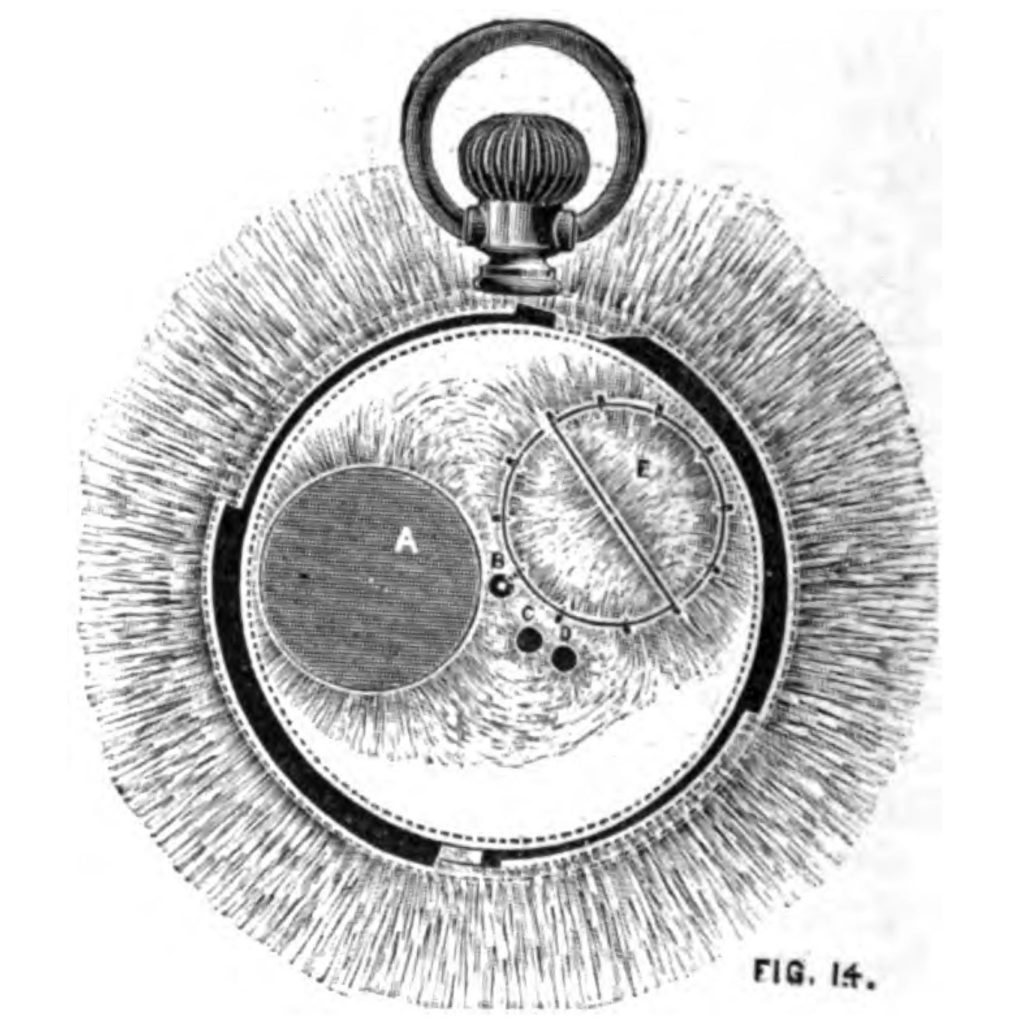

The quartz watch is a relatively modern invention, allowing accurate timepieces to be produced inexpensively. However, the watchmaking industry was using quartz well before the first quartz oscillator wristwatch was introduced to the world.

Standard enameling recipes called for colorless quartz to create the enamel powder used for watch dials. The pure quartz was mixed with tin oxide to produce the brilliant white color essential to the conventional watch dial.

The February 1883 issue of the Jewelers’ Circular and Horological Review describes the process:

“The best material to be employed in the manufacture of the ground masses for silicic acid are pieces of colorless quartz (rock crystal), which is red heated, thrown into water to render it brittle by a rapid cooling, and then pulverized… The white coloring substance in the ground mass, as already said, generally is tin oxide, to which sometimes lead oxide is mixed.”February 1883 issue of the Jewelers’ Circular and Horological Review

It was critical that no iron oxide was introduced into the mixture. Otherwise, the white dial would be ruined by a greenish tinge.

The mixture was melted and pulverized multiple times to create a consistent mixture that could then be applied to the copper dial blank prior to firing.

I have a Elgin pocket watch for a lady and would like to know more about it.

Elgin lookups are available in the database. I recommend starting here: https://pocketwatchdatabase.com/reference/how-to-lookup-a-pocket-watch