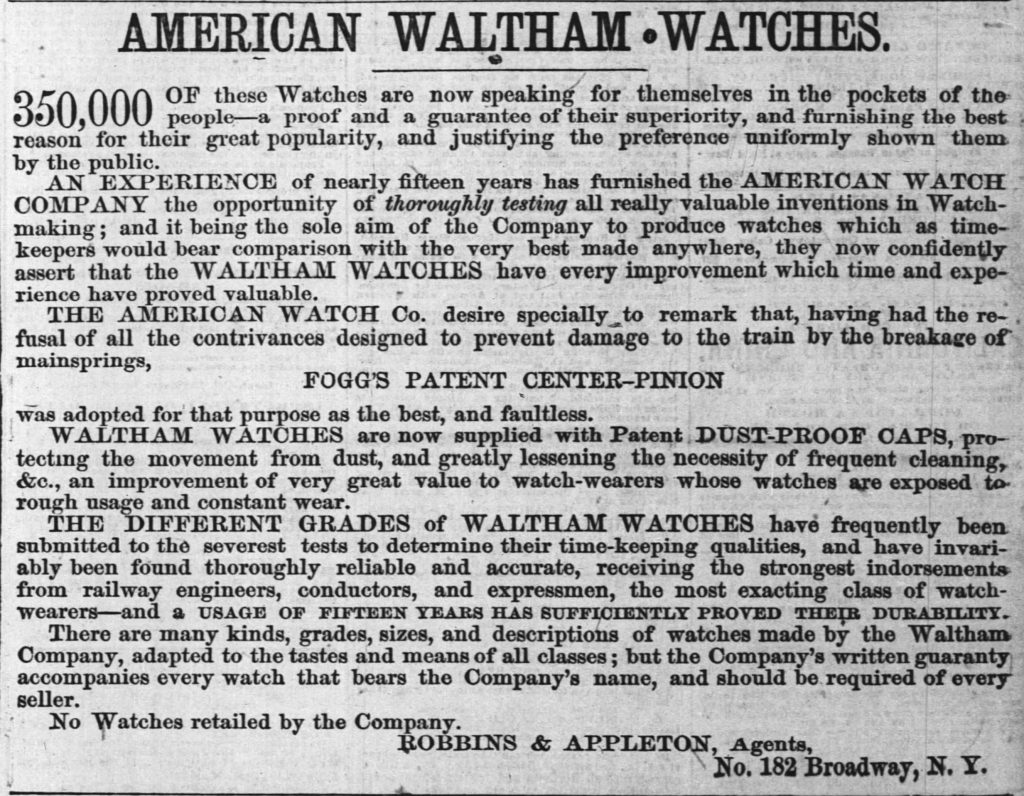

American Innovation: Charles W. Fogg’s Safety Pinion: The Better Patent Pinion (Part 3)

While Charles W. Fogg is generally credited with creating the first safety pinion in America, Merritt Burt actually secured a patent for his safety pinion design a few months before Fogg. Despite Burt being first, Fogg’s design was ultimately proven to be a more effective safety pinion.

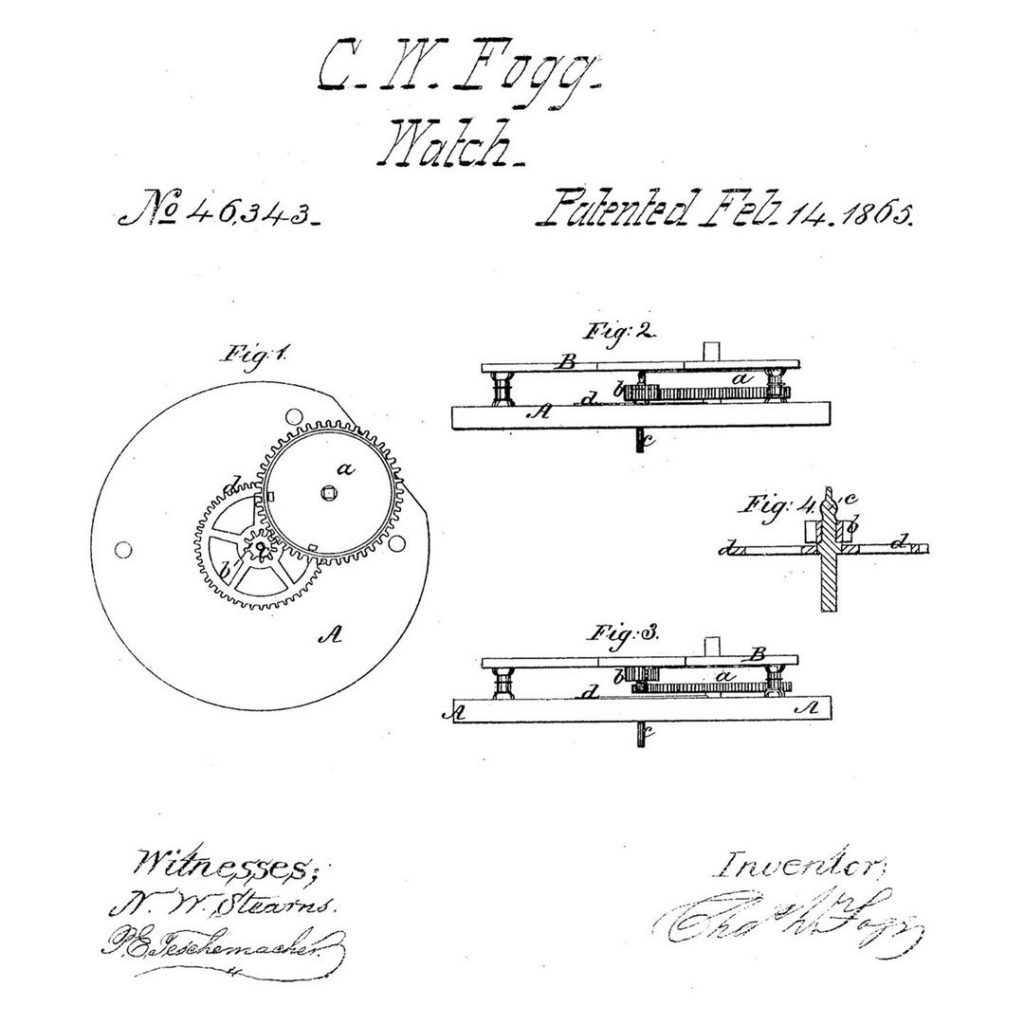

Charles W. Fogg secured a patent for his safety pinion design on February 14, 1865. During this time, Fogg was superintendent at the American Watch Company in Waltham, Massachusetts. While Merritt Burt received his patent without having a viable path for production, Fogg’s safety pinion was ready for immediate implementation in Waltham watch movements.

As a result, Fogg beat Burt to production and established a claim to the first safety pinion offered by an American watch company. It was only when the National Watch Company (Elgin) entered the market in 1867 that Burt’s safety pinion was realized in production.

The New York Times

Tue, Aug 25, 1868

Early Production with Fogg’s Safety Pinion

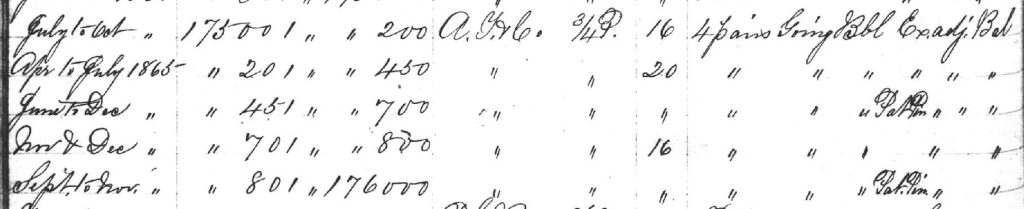

According to factory ledgers, the first run fitted with Fogg’s patented safety pinion commenced in June 1865. These movements were 20-Size, Appleton, Tracy & Co. grade, and assigned serial numbers 175,451-175,700. Shortly thereafter, a run of 16-Size Appleton, Tracy & Co. movements was produced with Fogg’s patent pinion, assigned serial numbers 175,801-176,000. (While these are the first noted in factory records, other runs may have been fitted with Fogg’s safety pinion and not designated as such).

Ledger from NAWCC Archive

Image Courtesy of Pocket Watch Database Contributor 8x57mauser

Comparing Safety Pinions: Burt vs. Fogg

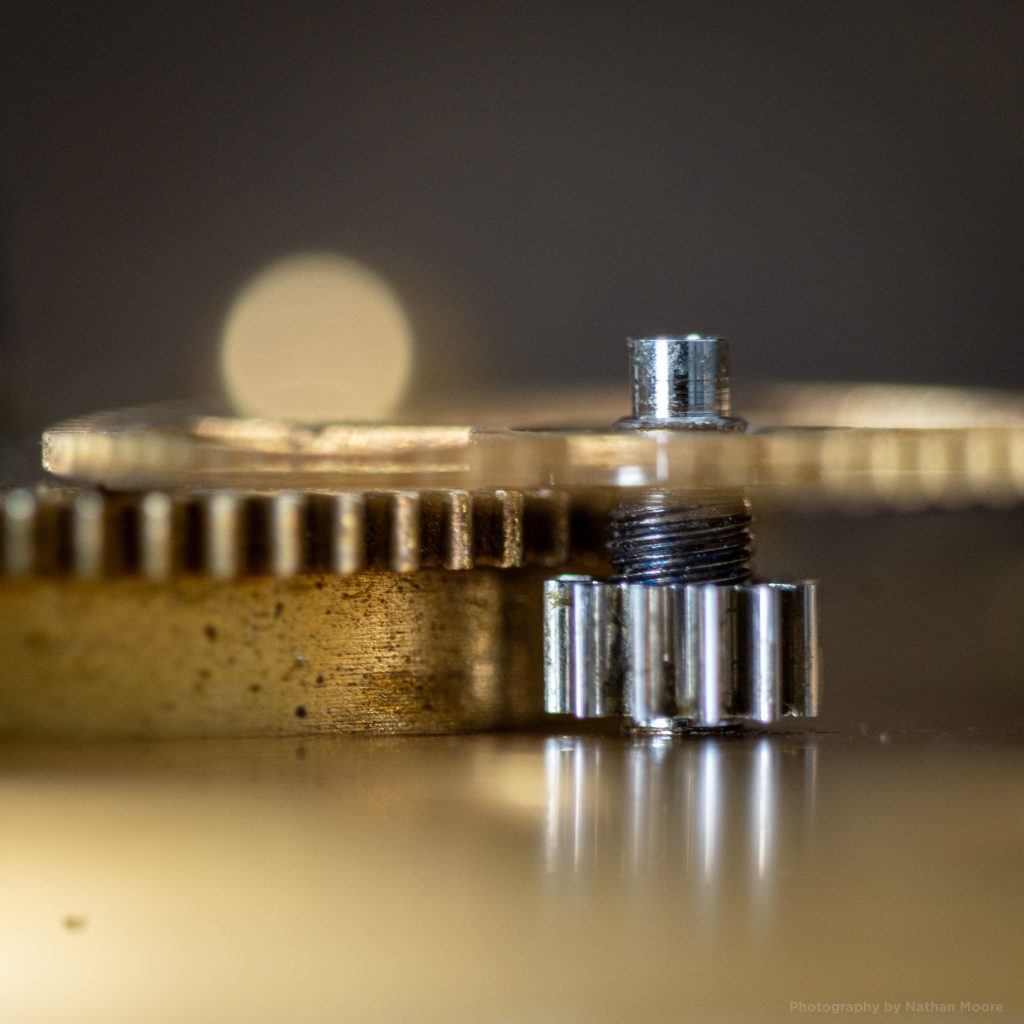

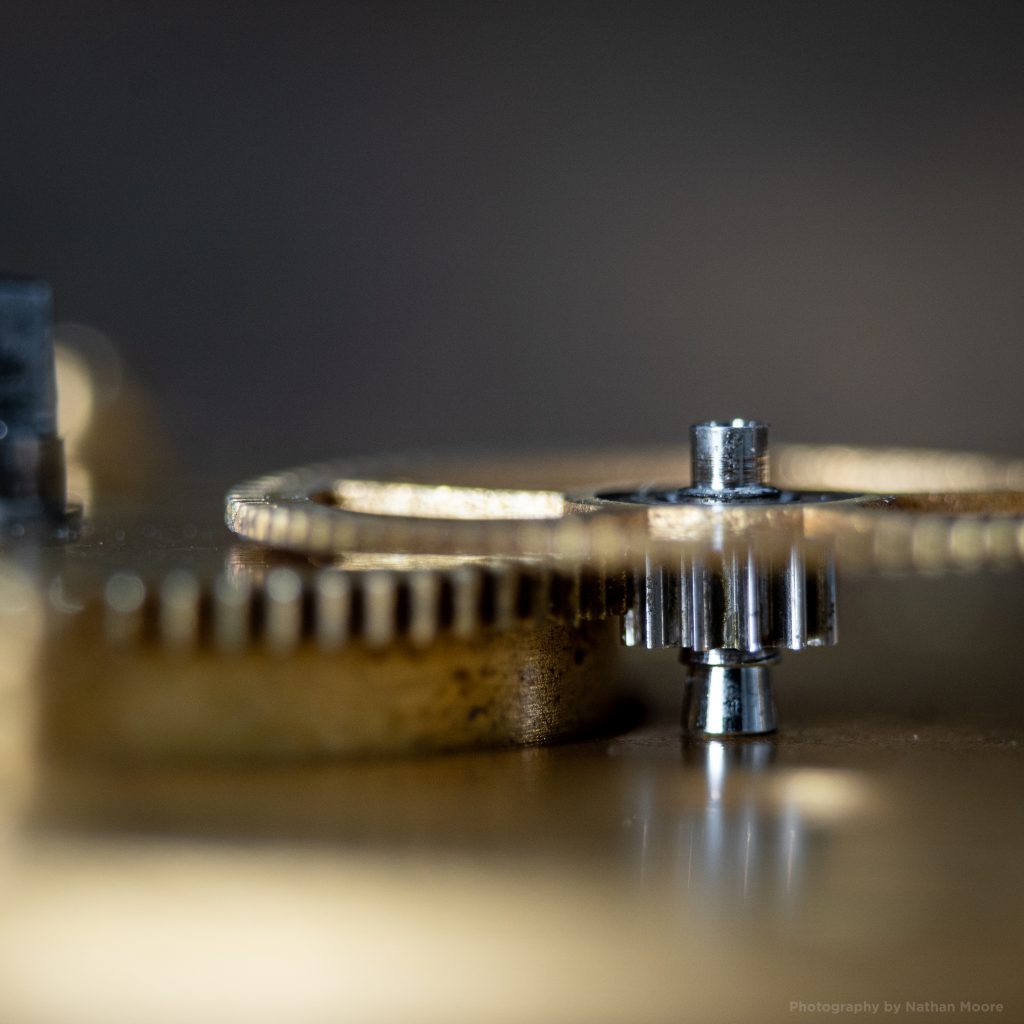

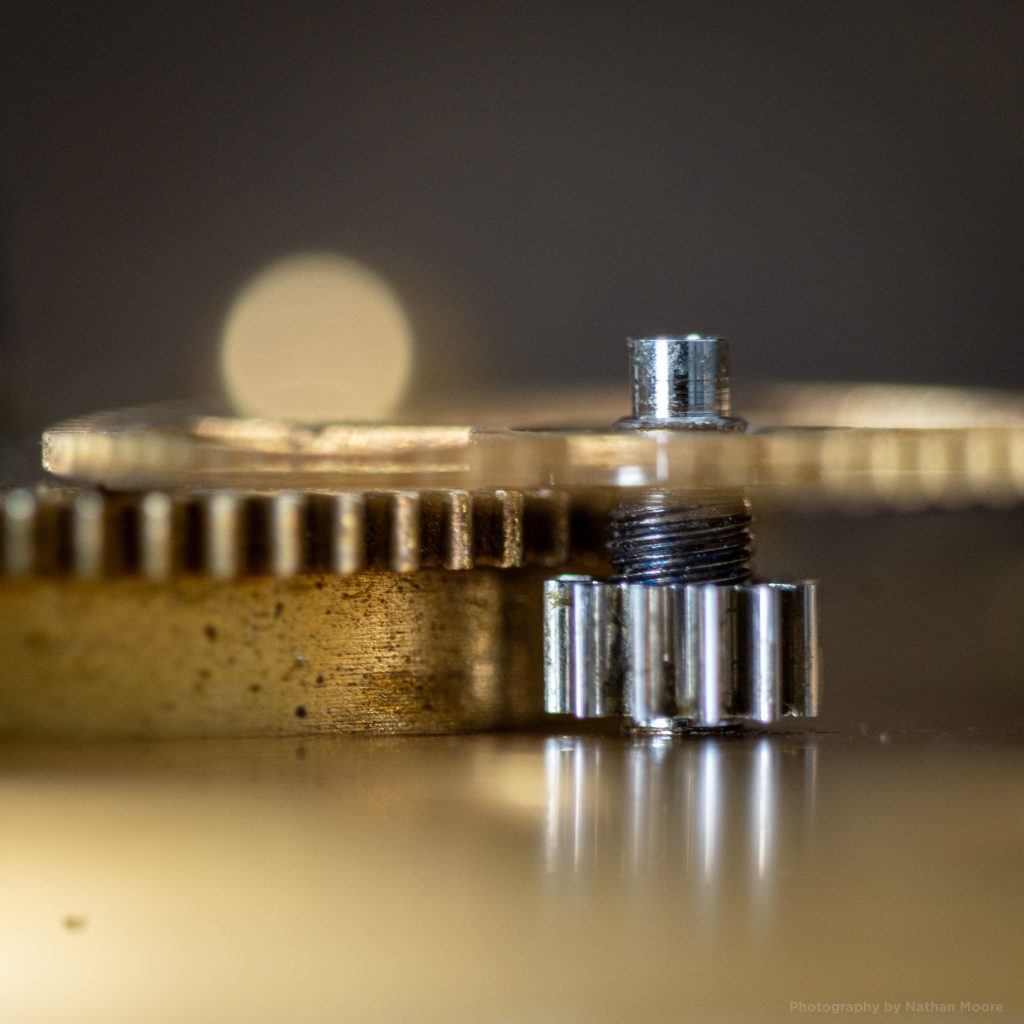

Both Burt’s and Fogg’s safety pinion designs relied on a threaded arbor on the center wheel that allowed the pinion to disengage when the mainspring broke. While the designs shared a similar concept, the implementations were slightly different, allowing both patents to be issued independently.

Merritt Burt’s design relied on a threaded nut that was tightened down onto a hollowed center pinion. When the mainspring broke, the force immediately loosened the nut and allowed the center pinion to spin freely on the center arbor until all energy was safely discharged.

In contrast, Fogg’s design was more elegant, relying on an internal thread inside the hollowed center pinion that was tightened directly on the center arbor. When the mainspring broke, the sudden backward force immediately unscrewed the pinion until it was free to spin until all energy was expelled.

The only benefit of Burt’s more complex design was that it also allowed energy to be released if the watch was wound with excessive force. However, that additional benefit was actually because the Achilles heel of Burt’s design, as the pinion, would sometimes slip unintentionally if the threaded nut was not tightened with proper torque.

Fogg’s Patent Application

In his patent application, Fogg describes the problem his invention was seeking to resolve:

“A great objection to that class of watches, where a going barrel is employed arises from the liability of the train to be damaged by the violent recoil resulting from the accidental breakage of the mainspring. To overcome this difficulty, a “stationary barrel” has been substituted for the going barrel; but this necessitated the employment of a “maintaining power” to prevent the stoppage of the watch when being wound up, and this arrangement, although it accomplished the desired result, was nevertheless complicated, and materially increased the cost of the whole watch.” U.S. Patent #46343

Fogg recognized the problem of the “stationary barrels” currently being utilized at the Waltham factory. The company was eagerly looking for a way to use the going barrel while saving the delicate watch parts when the mainspring violently broke.

“My invention has for its object to overcome all the above-mentioned difficulties, and still enable me to employ the going barrel; and it consists in attaching one of the pinions of the train to its arbor by means of a screw-thread, so that when it is driven in the direction in which it is intended to run it will be kept down in place; but in the event of the breakage of the mainspring the force of the recoil will revolve it in the opposite direction, and cause it to rise on its arbor out of gear with the wheel into which it takes, thereby avoiding all liability of derangement of the train, and enabling me to retain the advantages of the going barrel without danger of the train being injured by the recoil.” U.S. Patent #46343

Fogg concluded his application by defining the essence of his design:

“Attaching one of the pinions of the train to its arbor by means of a screw-thread, substantially as set forth, for the purpose specified.” U.S. Patent #46343

With this specific definition, Charles W. Fogg was able to receive a patent for his design without infringing upon Burt’s patent. Fogg’s design relied on an internally threaded pinion, while Burt’s design relied on a nut that tightened on top of a revolving pinion that became friction-set.

The train of the watch has been saved, and the pinion only requires to be screwed back into place during service.

The Legal Battle: Elgin vs. Waltham

Even though Burt and Fogg both rightfully secured patents for their respective designs, the National Watch Company (Elgin) believed the concept was too similar and claimed the American Watch Company (Waltham) was infringing on Burt’s patent.

According to Charles S. Crossman’s historical summary of The American Waltham Watch Company, originally published in the November 1886 issue of The Jewelers’ Circular and Horological Review, this conflict led to a legal challenge before the companies came to an agreement.

“Mr. C.W. Fogg’s center pinion which he patented in 1865, was adopted by the company to a limited extent during that year. They had previously tried to use D.B. Fitts’ patent reversible center pinion with rachet and click arrangement but found it was not a desirable device. A suit at once grew out of their using Mr. Fogg’s pinion, as the Elgin Watch Company claimed it was an infringement on Burts’ patent pinion they were using. […] The infringement seemed plain, but the suit resulted in an amicable settlement, each company agreeing to allow the other to use their patented improvements and inventions without interference.”

With the success of both Burt’s and Fogg’s patented designs, the safety pinion became an industry standard for quality watches on the market. When new watch companies were organized in the 1870s, a safety pinion design was considered a necessity for production. One of the first patents secured by new companies was typically some form of a safety pinion.

Wonder if mr fogg benefited monetarily from his patent aside from continued employment with waltham?

Another item of interest is the proper servicing of the fogg safety pinion? Winder how many are not released and reset during service. And what was actually required to maintain their protection of the train?