What is the Elginium Hairspring?

The Elgin National Watch Company introduced the Elginium hairspring in 1938. During this era, American watch companies were urgently competing to develop new technologies that would propel their products to the forefront of the market.

Elgin was looking for a unique alloy to produce a hairspring that could compete with the “Elinvar” hairsprings fitted on watches manufactured by the Hamilton Watch Company.

In the c.1940 Elgin Service Bulletin, the Elgin National Watch Company boasted about the recent technologies that had been implemented at the factory, including the Elginium metal alloy:

Here, in the world’s largest factory, these master American craftsmen, in partnership with expert scientists, have achieved outstanding technical advances. Among these are the patented Elginium hairspring, the famous Beryl-X balance, an the patents grooved balance staff. c.1940 Elgin Service Bulletin, Page 1

“Elginium” was advertised by the company as being rust-proof, non-magnetic, and self-compensating – three characteristics that would improve the precision and longevity of the hairspring.

The c.1940 Elgin Service Bulletin describes the advantages of the “Elginium” hairspring:

Elgin watches today are equipped with the marvelous new self-compensating ELGINIUM hairpsrings and BERYL-X solid balances.

ELGINIUM is a special alloy which is practically unaffected by changes in temperature. Exclusive with Elgin, it is protected by registered trade marks and by Patent Nos. 1,974,695 and 2,072,489.

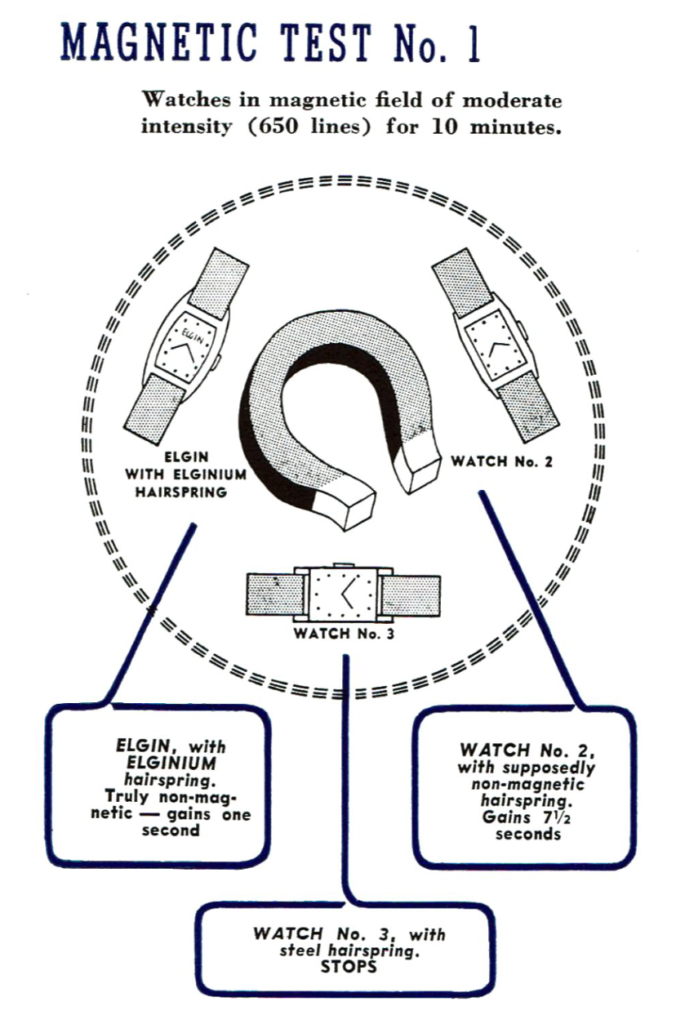

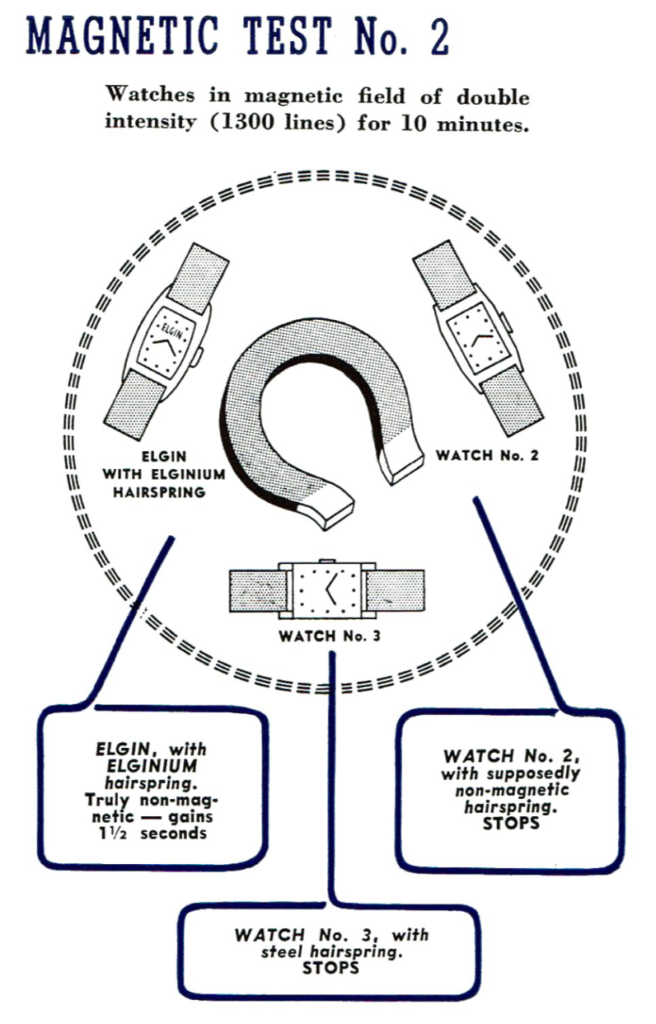

Illustrations below show the comparative action of ELGINIUM and of ordinary hairsprings under magnetic conditions. For example, if a series of three watches were placed in the field of 650 lines per square inch created by a magnet, watch No. 2, and Elgin equipped with ELGINIUM hairspring, watch No. 2, containing a supposedly “non-magnetic” hairspring, and watch No. 3, containing a steel hairspring, the astonishing superiority of ELGINIUM harisprings would be demonstrated as shown in the chart below. If placed in a magnetic field of 1300 lines, watches No. 2 and No. 3 would cease to function entirely, as shown in the second chart. c.1940 Elgin Service Bulletin, Page 4

The first patent granted for one of the alloys used for the Elginium hairspring was granted on September 23, 1934 to Reinhard Straumann of Waldenburg, Switzerland. The patent application briefly describes the problem his alloy is intended to improve:

“The known nickel-iron alloys, as are used for example in the manufacture of spiral springs for watches, with positive thermo-elastic coefficient, have the great disadvantage of too low hardness. The springs heavily damp the vibrating system, which among other disadvantages leads in particular to large energy losses. Further, such springs easily deform which makes their use in marine chronometers impossible owing to the permanent deformations of the end curves produced as a result of the low hardness. These known springs are brought to glowing heat in the fixation of their shape taking place at high temperature (600 to 700 C.) and thus lose the hardness produced in rolling.” U.S. Patent #1974695

Straumann’s alloy was created with the addition of Beryllium, as described in the documentation:

“The present invention relates to a spring of nickel-iron alloy with a hardening addition of beryllium, in particular for thermo-compensated vibrating systems, in which the increase of hardness of the spring takes place during the fixation of the shape thereof and in which the thermoelastic requirements are completely satisfied.” U.S. Patent #1974695

The patent protected alloys described by Straumann as composed of 25-40% nickel, 0.1-3% beryllium, and other alloying ingredients up to 30%, such as tungsten, molybdenum, and chromium.

The second patent related to the Elginium alloy created by Straumann was granted on March 2, 1937. The patent application is extremely similar to the original patent except for the addition of chromium-beryllium is represented as a more prominent component in the alloy combination.

The manufacture rights secured by these two patents were assigned to the Elgin National Watch Company to produce the Elginium hairspring.

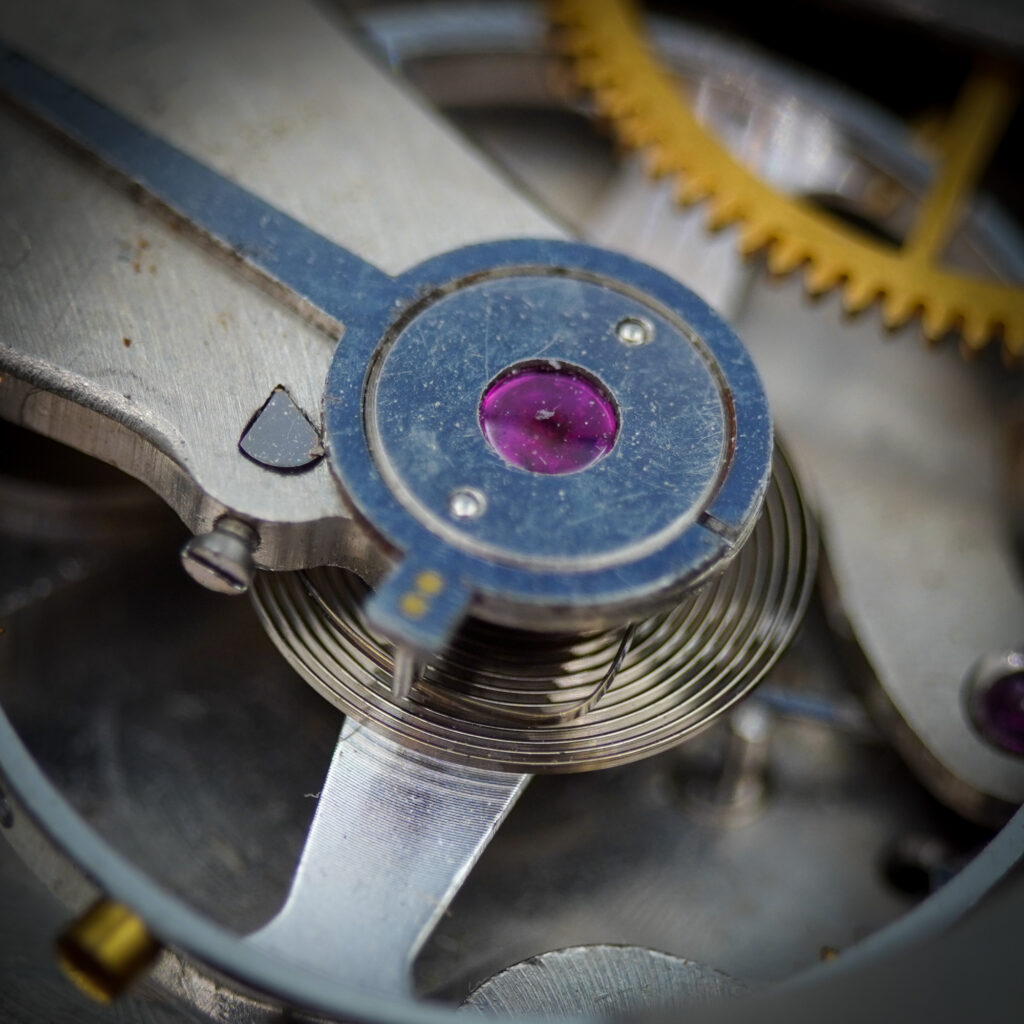

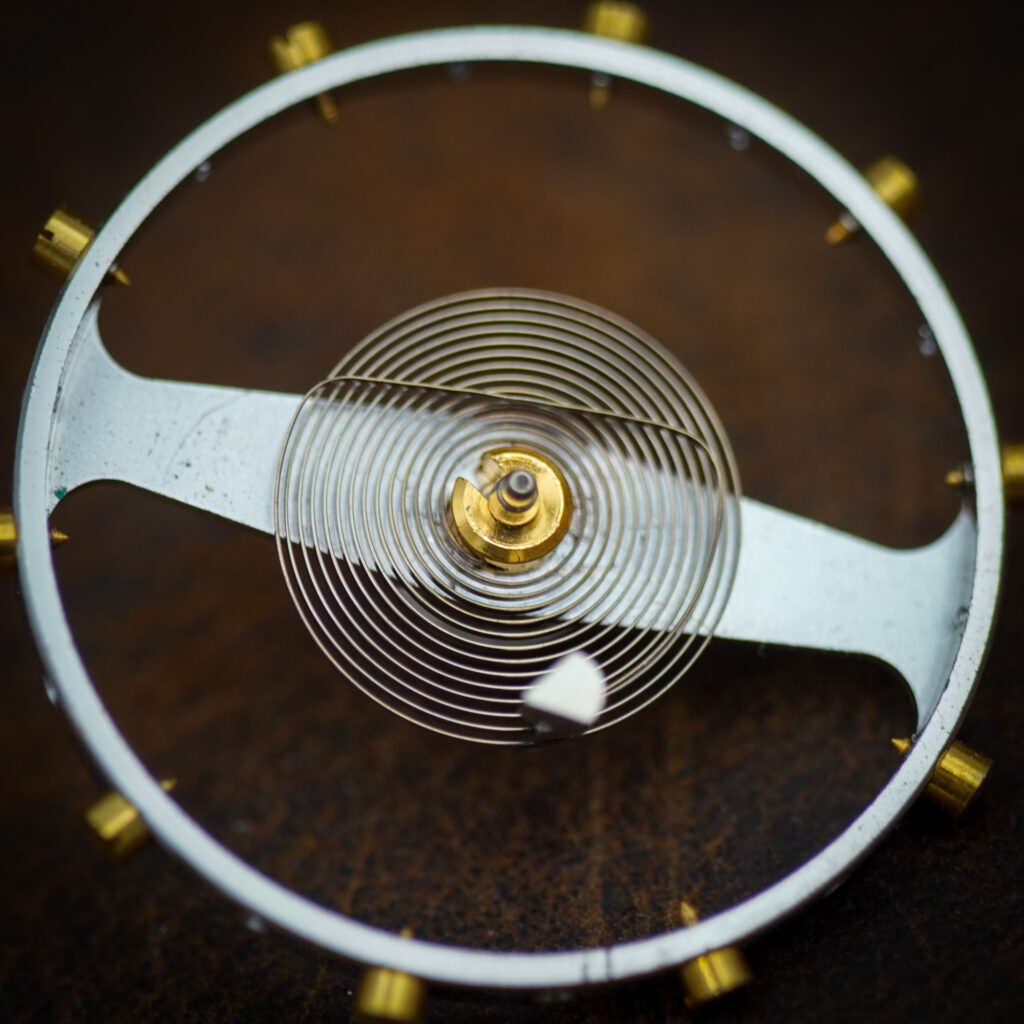

The Elginium hairspring can be identified on Elgin watches manufactured after c.1938. The hairspring will feature a white silvery finish instead of the blueish color on traditional steel hairspring. The Elginium hairspring is also typically paired with a Beryl-X solid balance, which was introduced around the same time.