The Waltham “Crescent Street” Movement: The Model 1870: Fogg’s Patent Safety Pinion and Bingham’s Patent Dust Ring

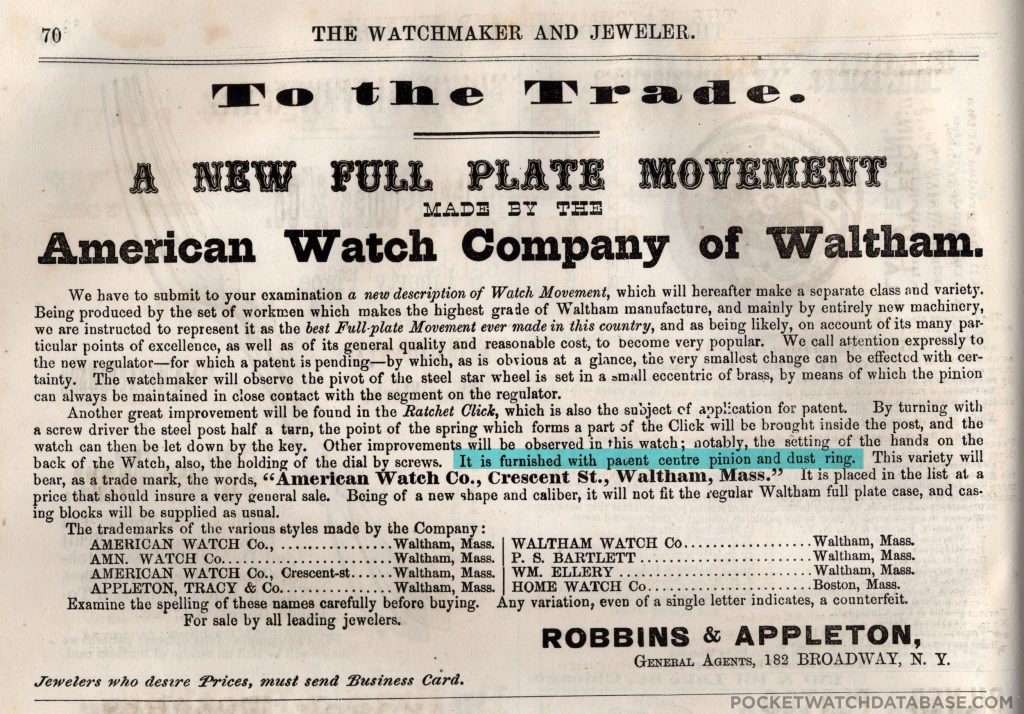

When the “Crescent Street” movement first debuted, it included several new features designed to quickly capture the growing railroad market. These features were detailed in advertisements published by Robbins & Appleton, general sales agents for the American Watch Company.

Two features already proven successful in other Waltham products were also implemented when the Model 1870 Crescent Street was designed – Charles W. Fogg’s Patent Safety Pinion and B.D. Bingham’s Patent Dust Ring. Both innovations helped protect the movement and improve longevity.

Fogg’s Safety Pinion

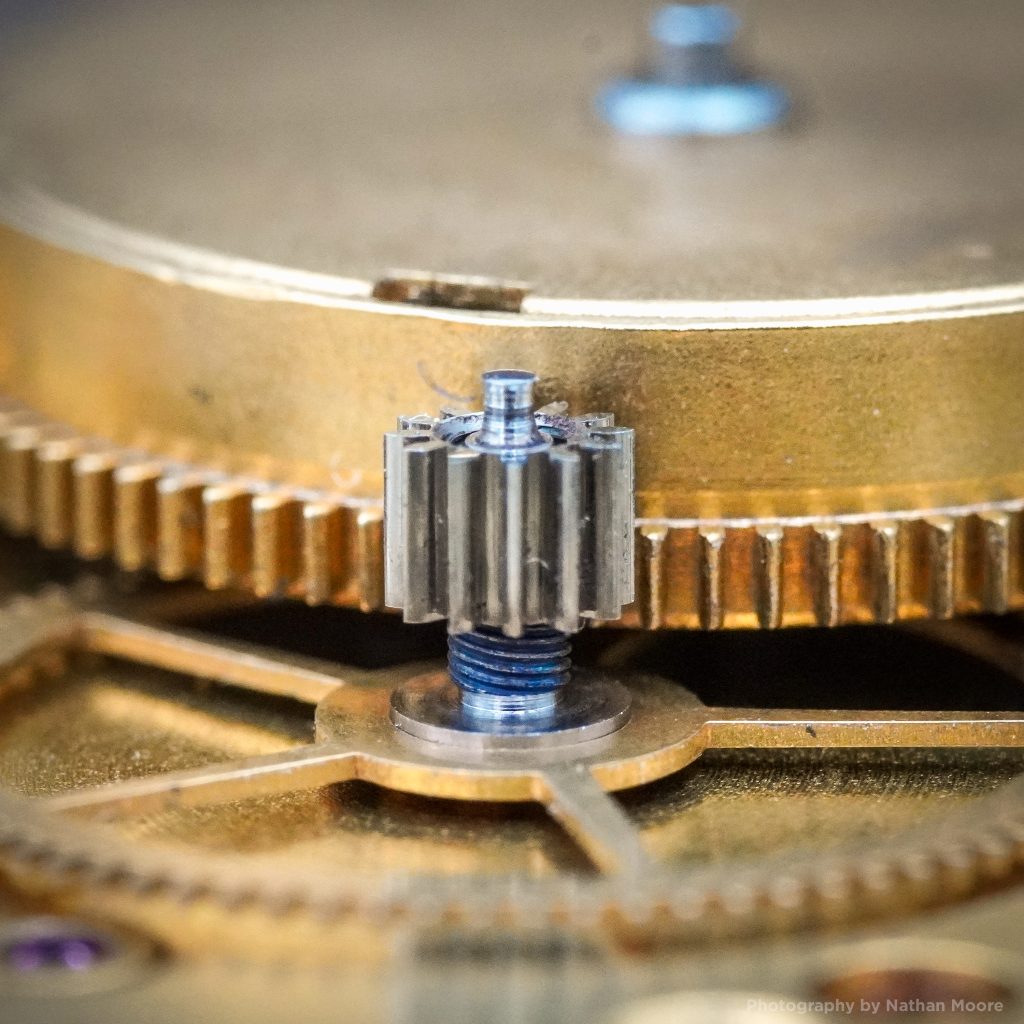

Charles W. Fogg received a patent for his reversible center pinion in 1865, representing the first safety pinion executed in production at an American watch factory. Fogg’s design functioned using a threaded center arbor and an internally threaded hollow pinion. When screwed down onto the center pinion, the wheel functioned normally, transferring power from the main wheel to the rest of the train. However, if the mainspring failed, the sudden force applied in the opposite direction would loosen the center pinion, allowing the destructive energy to be expelled safely. This simple mechanism saved the delicate parts from damage and allowed the American Watch Company to sell more expensive watches with the newfound confidence of potential customers.

Bingham’s Dust Ring

Dust is one of the inevitable downfalls of a watch movement. Little by little, tiny particles can build up around the pinions and in the bearings of the watch, causing problems for the timekeeping capabilities. This was especially true during the keywind era when watches were constantly opened to wind and set the watch. Dust caps and key guards provided basic protection, but dust would still find its way into the watch’s internal mechanics.

While working at the Tremont Watch Company, B.D. Bingham designed a ring that would fit tightly around the watch movement, shielding the internal cavity from dust and debris. Bingham received a patent for his design on February 4, 1868.

Shortly after the Tremont Watch Company failed, the American Watch Company (Waltham) secured the rights to use Bingham’s patent in production. This simple invention improved the longevity of the watch as the internal components were not as vulnerable to dust buildup over time in the same way an unprotected movement was.

Other watch companies soon followed, developing their own devices to prevent dust from entering between the plates of the movement.

Perfect for the Model 1870

These two innovations were perfect to meet the high standards of the new Model 1870 Crescent Street. This was especially true in the rugged environment the watches were exposed to during everyday railway service. The introduction of the Crescent Street raised the expectations for watches used for timekeeping on American railroads.