American Innovation: The Hampden Watch Company “Spring Staff” Patent Safety Pinion (Part 8)

Different Approach

The patented safety pinion designs by Burt, Fogg, and Moseley all operated by means of a center pinion that would disengage from the center staff when the mainspring broke, allowing the destructive force to be expelled without damaging the delicate components. This typically required a watchmaker to “reset” the pinion after replacing the mainspring.

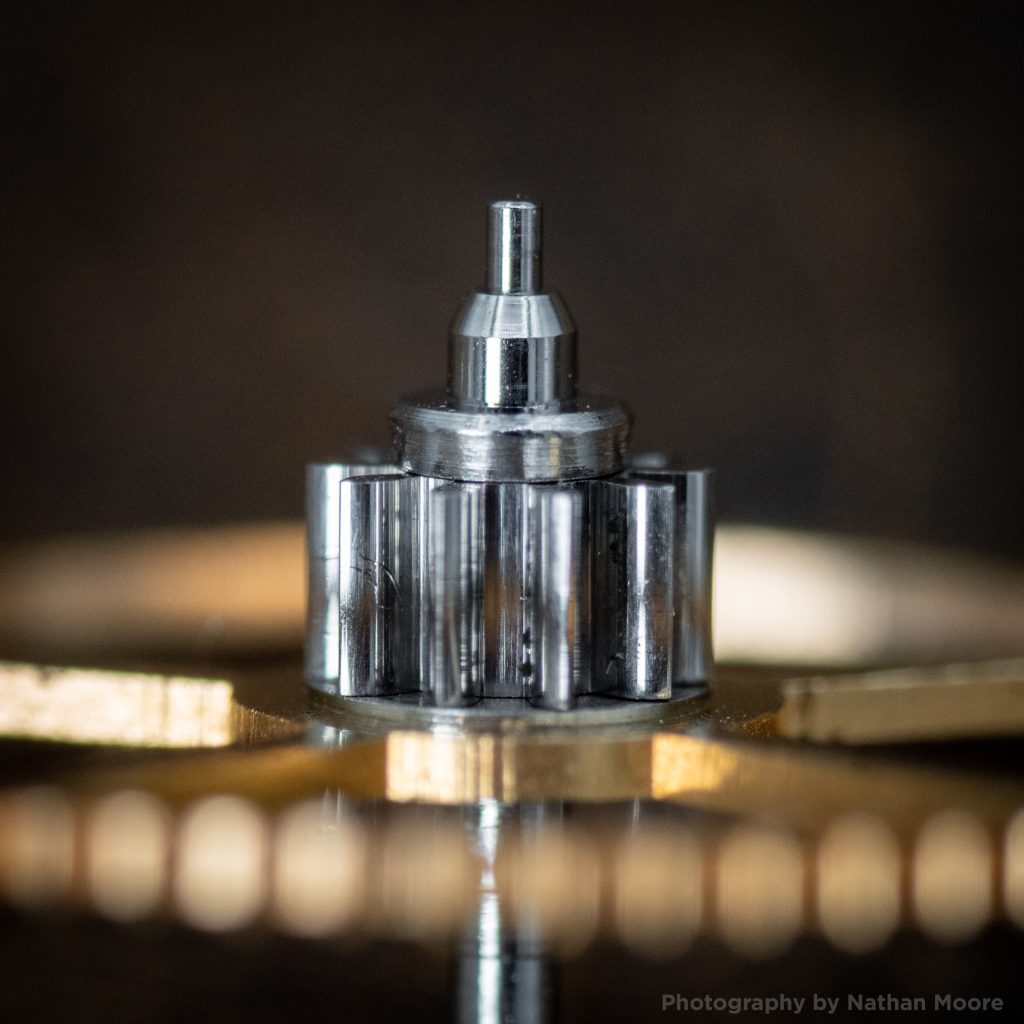

In contrast, the safety pinion design implemented by the Hampden Watch Company did not rely on separating the center pinion from the staff to safely disperse the destructive energy applied when the mainspring broke. Instead, the novel design allowed for the pinion to rotate freely in one direction but would “catch” in the other direction, allowing for normal operation.

This was accomplished by an almond-shaped spring placed on a flattened segment of the center staff paired with a catch provisioned inside the center pinion. When the pinion is rotated for regular operation, the side of the spring catches and binds the pinion, allowing the center wheel to transmit the force applied from the mainspring barrel. However, when the mainspring breaks, the sudden force is applied in the opposite direction, and the pinion is allowed to ride over the spring with each revolution. When rotated manually, this action produces a small clicking sound as the spring snaps back when the catch inside the pinion passes.

Images of the Hampden Safety Pinion

This design allows the pinion to remain engaged with the staff, automatically resetting when it is rotated in the opposite direction again.

Patented Design?

During the 1870s, safety pinion designs used in production were typically patented through the U.S. Patent Office. However, no patents have been located detailing the design used by the Hampden Watch Company. It is unknown whether a patent was applied for and denied or if the company simply decided to forgo the formal application route.

Interestingly, despite no patent being granted, the company marked movements with this improvement, “Pat Pinion” or “Patent Pinion,” suggesting the design was protected by a patent.

George Hunt’s Patented Design

George Hunt, the master watchmaker and superintendent at the New York Watch Company prior to its reorganization as Hampden, patented a similar safety pinion design in 1873. The design used by Hampden was possibly a derivative of Hunt’s original design since the general operating principle employed for the safety provision is the same. However, several notable differences suggest that the design would not have been protected by Hunt’s original 1873 patent. Additionally, by the time Mr. Hunt patented his safety pinion design, he was no longer employed at the Hampden factory.

Terminology

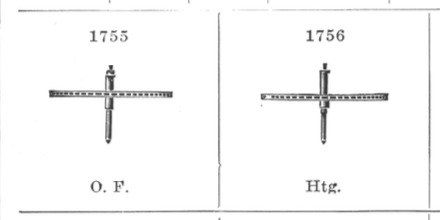

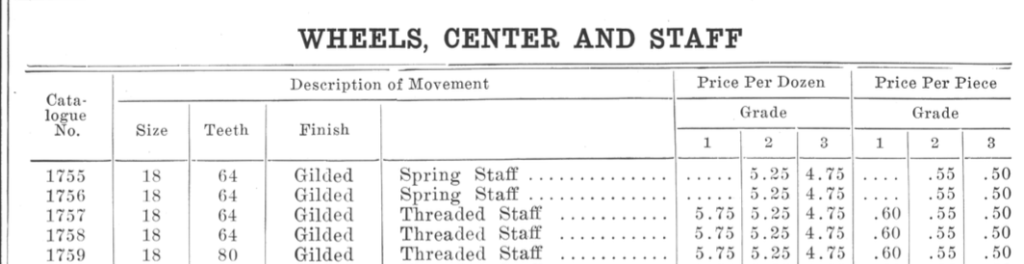

In material catalogs distributed by the company, the term used to differentiate this early safety pinion design was “spring staff,” referencing the small spring utilized for the binding action against the center staff. According to the 1915 Hampden Watch Company material catalog, the “spring staff” safety pinion design was only implemented on 18-Size movements with a coarse train.

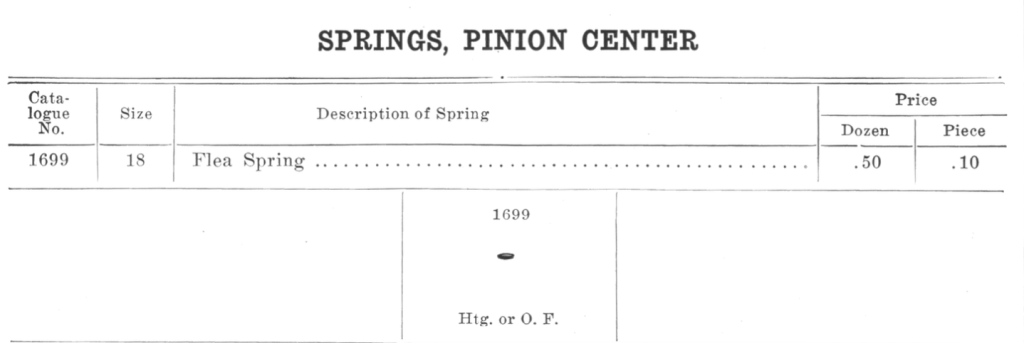

The spring used inside the safety pinion was called the “Flea Spring” in material catalogs due to its small size.

Introduction & Production

Movements produced at the Hampden factory began to appear with the “Pat. Pinion” marking around 1877, suggesting the safety pinion design was introduced around the time the company was reorganized from the failing New York Watch Company.

The “Spring Staff” design was utilized by the Hampden Watch Company until the 1880s, when the conventional “Fogg” threaded staff safety pinion replaced the complicated spring design, following the industry trend.