American Innovation: Charles S. Moseley’s Patent Safety Pinion: Improving Merritt Burt’s Design (Part 5)

Charles S. Moseley joined the National Watch Company in 1864 after being lured away from the American Watch Company in Waltham. Moseley exhibited a brilliant mechanical mind and was offered the position of superintendent and master mechanic at the new Elgin factory.

As the National Watch Company gained momentum in the market, Moseley continued to secure patents for his designs, leaving a lasting legacy in the American watch industry.

One of Moseley’s first innovative designs patented at Elgin was the iconic “pie shape” hairspring stud, implemented in Elgin movements for nearly a century.

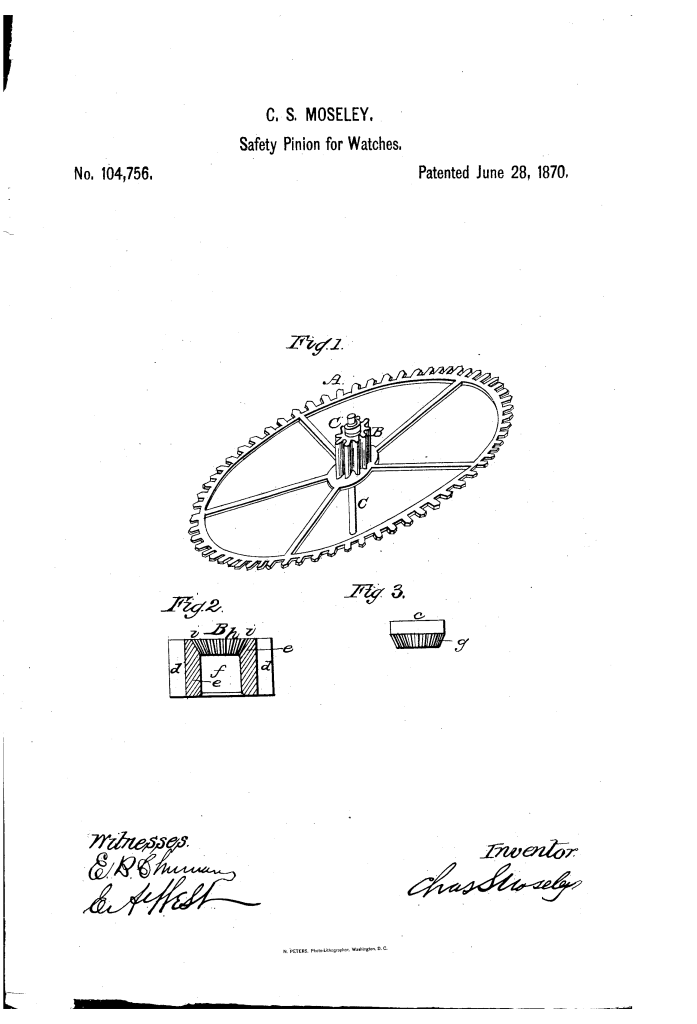

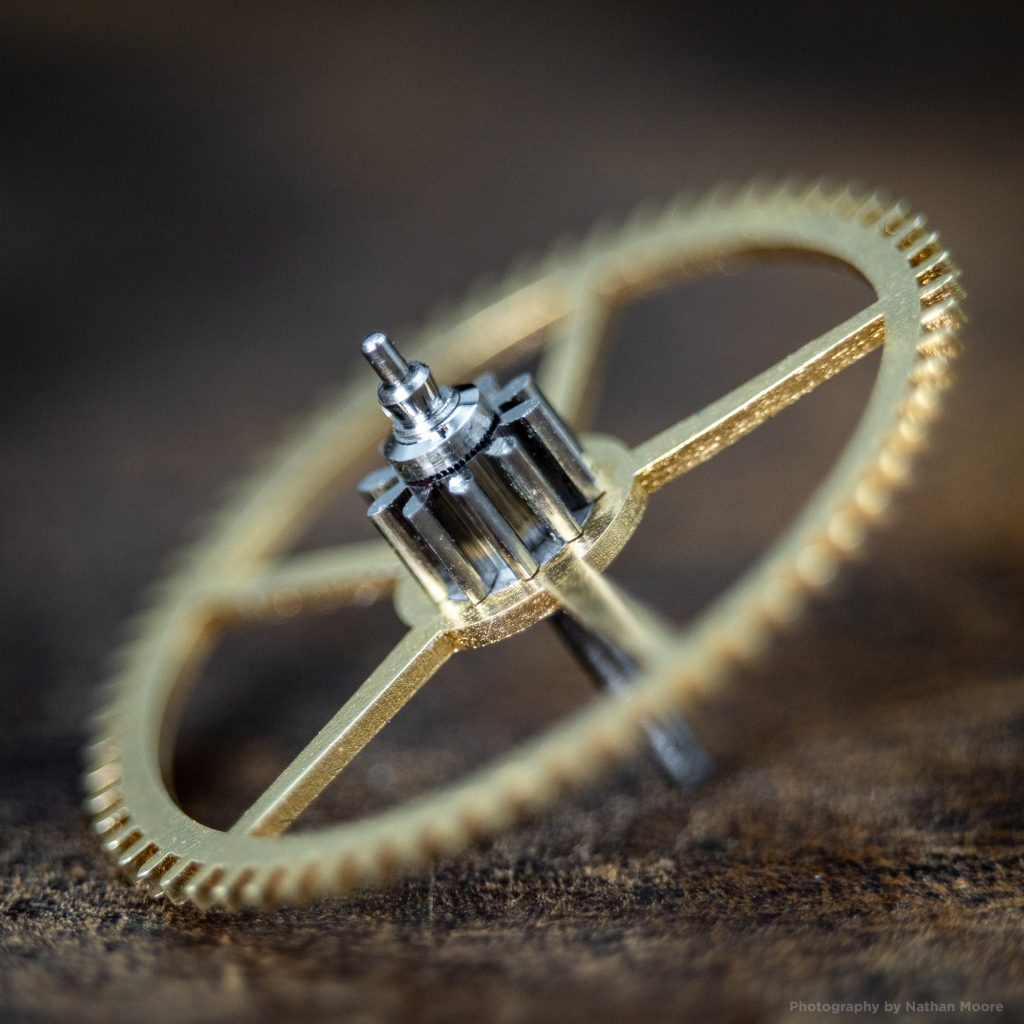

On June 28, 1870, Moseley patented an improved safety pinion design. The National Watch Company (Elgin) had used Merritt Burt’s safety pinion since it introduced its watch movements to the market in 1867.

One flaw in Burt’s design was that the hollowed pinion could unintentionally slip if the threaded nut was not tightened with the perfect amount of torque.

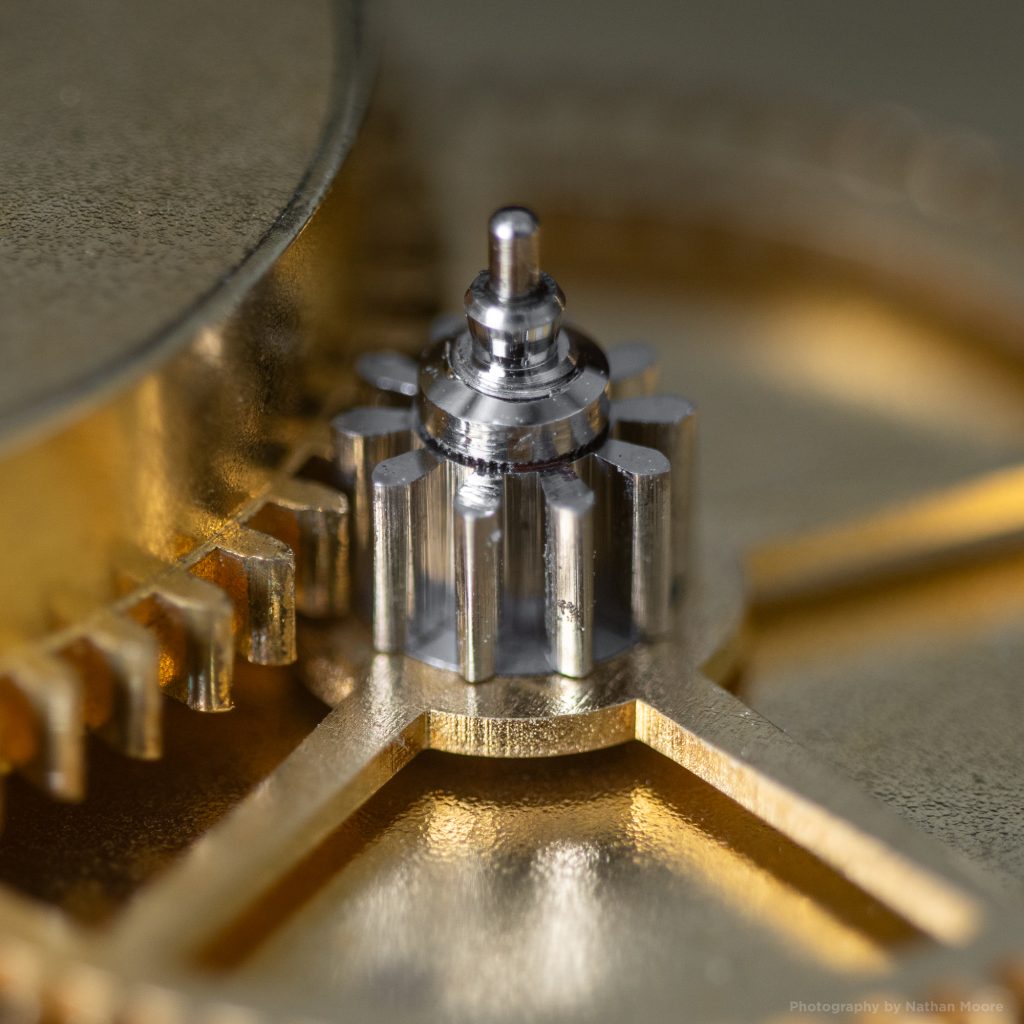

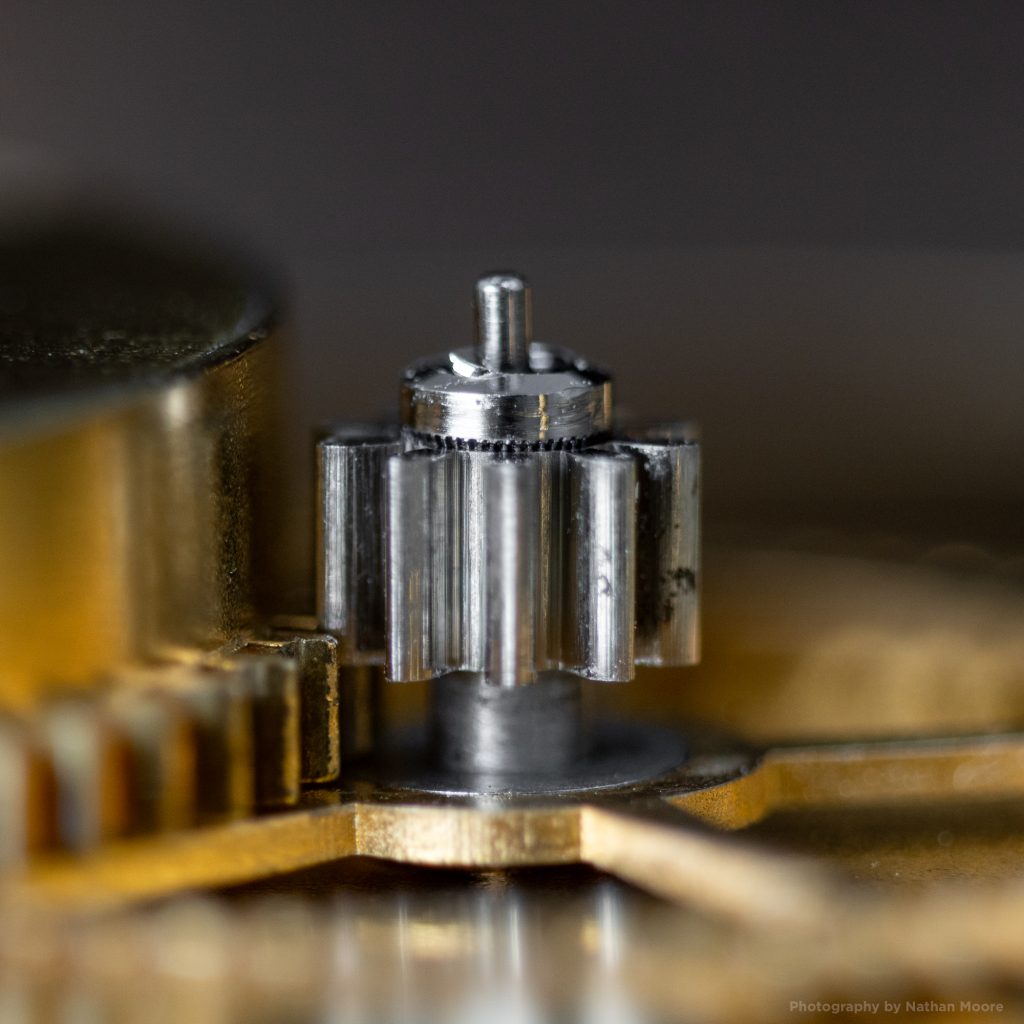

Moseley corrected this flaw by adding a corrugated surface to the top of the center pinion and the bottom of the nut, effectively binding the two pieces together when paired. This addition prevented the pinion from unintentionally slipping while still allowing it to disengage immediately when the mainspring broke.

According to Moseley’s patent documentation, his design was actually an alternative to Benjamin Bacon’s safety pinion design – Elgin’s first attempt to correct the flaws in Burt’s design. However, as far as we know, Bacon’s design was never implemented into production movements, and Elgin was still searching for a solution to resolve the flaws in Burt’s safety pinion.

Moseley described his safety pinion in his patent application:

“This has been accomplished by the use of a loose pinion on the shaft of the center wheel; and I am aware that, to be used with such loose pinion, a nut has been made having one or more lugs or points projecting downward from the under side of the nut, and, passing between the leaves of the pinion, so far connecting the nut and pinion that the two move together, preventing the slipping of the pinion between the nut and wheel.”

“There are serious objections to this method of connecting the nut and pinion. It is difficult and comparatively expensive to make the nut with these lugs, and they are liable to become broken or detached from the nut, and hence are not entirely reliable.” U.S. Patent #104756

Because Moseley’s improved safety pinion coupled the nut and the hollowed pinion, the winding of the mainspring provided enough force to secure the center pinion in the operational position. When the mainspring broke, the barrel would instantly spin in the opposite direction, loosening the pinion and alleviating the destructive force safely.

While the patent document suggests the nut and pinion were separate pieces, inspecting surviving examples has revealed that they were essentially melded together as one piece in practice. This caused the entire pinion to behave more like Fogg’s safety pinion design used in Waltham watches.

Moseley’s safety pinion can be identified by inspecting the top of the center pinion under magnification. As specified in the patent documentation, a grooved or corrugated surface is evident where the threaded nut meets the center pinion. Elgin movements fitted with Burt’s or Moseley’s safety pinion are typically marked “Patent Pinion,” while movements with the standard safety pinion derived from Fogg’s design can be identified by a “Safety Pinion” marking.

Moseley’s design was used in Elgin watches for nearly two decades as the primary method of preventing damage when the mainspring unexpectedly broke.

In 1882, the safety pinion originally patented by Charles W. Fogg entered the public domain, permitting other companies to use his design freely. Because of the elegance and effectiveness of Fogg’s design, it was adopted as the standard for safety pinions in the market.

The National Watch Company eventually revised the design for its safety pinions to a “New Style,” discontinuing the use of the threaded nut.